💡 The Challenge: Not Just “Buying a Fan,” But Winning a Project

When one of our clients received a high-spec tender request for a thermal management system in a high-density storage cabinet, the requirements were far beyond a standard off-the-shelf fan.

The fan needed to follow a precise multi-stage temperature control logic:

- Below 35°C: Fan remains stopped (Standby Mode)

- At 35°C: Runs at 50% speed

- At 40°C: Runs at 70% speed

- At the maximum limit: Runs at 100% speed

- If stalled: Immediately triggers an alarm

This meant the fan had to include both intelligent control logic and built-in fault detection, not just mechanical performance.

The client needed a partner who could not only supply hardware but co-engineer a complete intelligent fan solution to help them win the bid.

🧠 Step 1: Deep Technical Analysis — Beyond the Specification Sheet

The client’s original design specified a sound alarm to indicate when a fan stalls.

However, through our professional experience in industrial cooling applications, MEGA engineers quickly identified a hidden problem:

Audible alarms are unreliable in high-noise environments.

- Industrial sites or data rooms often exceed 80–90 dB — making sound alarms hard to notice.

- Even if the alarm is heard, locating the exact fan or cabinet that failed takes valuable time.

This diagnostic delay can lead to equipment downtime or even system damage.

💡 Step 2: Visual Lock — Replacing Noise with LED + System Alerts

To solve this, MEGA proposed a smarter approach:

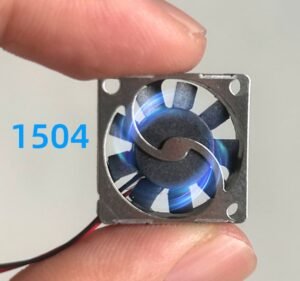

- Custom Stall Detection Logic: Embedded into the fan’s PCB, allowing instant detection of fan stall conditions.

- LED Visual Alert: When a fan stalls, its blue LED indicator lights up immediately. In large arrays, this allows instant identification of the faulty fan.

- System Synchronization: At the same time, the stall signal is sent to the main control system, triggering a digital alert in the client’s software interface.

✅ Result:

This “Visual + System Alert” dual feedback mechanism ensures instant localization of faults — far faster than any sound alarm could provide.

⚙️ Step 3: Precision Thermal Logic — Four-Level Temperature Control

To meet the tender’s performance criteria, MEGA designed and validated a custom 4-stage control curve, ensuring stable performance across temperature thresholds:

| Temperature | Fan Speed | Function |

|---|---|---|

| <35°C | 0% | Standby / Energy Saving |

| 35°C | 50% | Low Power |

| 40°C | 70% | Load Boost |

| ≥Max | 100% | Full Protection |

This intelligent fan logic delivers high cooling efficiency with optimal power consumption, aligning perfectly with the client’s system-level energy-saving goals.

🎬 Step 4: Proof of Expertise — Real Project Demonstration

Before finalizing, we presented the client with a real test video from a previous project where MEGA successfully implemented a similar multi-level control and stall detection system.

This evidence gave the client full confidence that MEGA’s solution was tested, reliable, and production-ready.

🧩 Step 5: Full-Process Technical Support — From Power Scheme to Installation

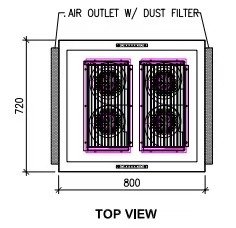

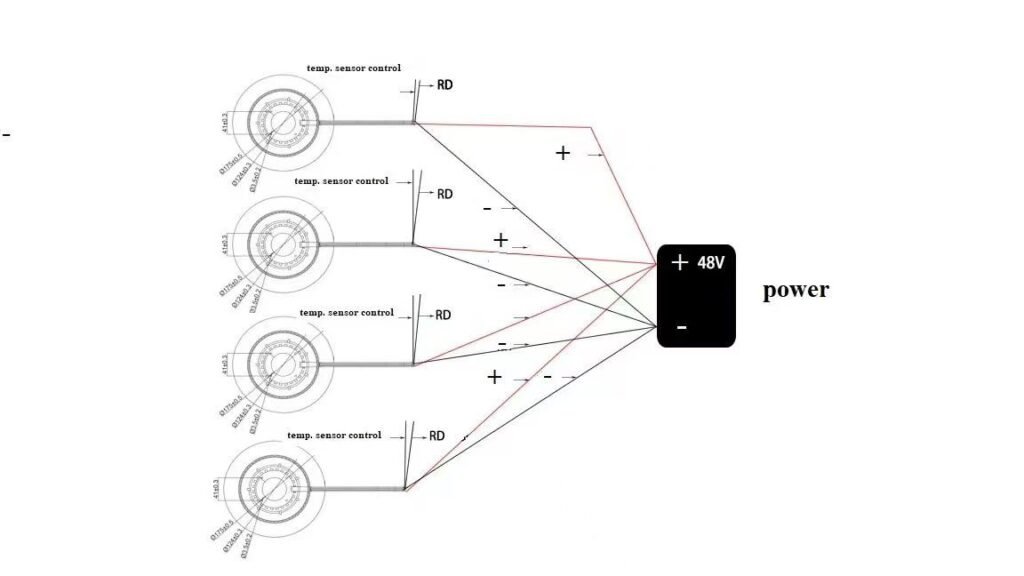

Winning the tender was just the beginning. MEGA provided complete engineering documentation and support, including:

- Power Optimization Scheme: Showing how one power controller could efficiently supply four fan units, simplifying wiring and reducing system cost.

- Installation Drawings & Guides: Clear 2D installation diagrams and step-by-step assembly instructions ensured the client’s team could integrate MEGA fans perfectly.

This comprehensive technical support helped the client accelerate system integration, meet the tender’s deadlines, and ensure long-term reliability.

🤝 The Result: From Supplier to Technical Partner

In this project, MEGA FANS wasn’t just a supplier — we became the client’s cooling solution consultant.

Our end-to-end support — from design logic to testing and documentation — was a critical factor in helping the client win their high-spec tender.

If your next project requires custom fan control, unique thermal logic, or integrated monitoring capability —

stop compromising with generic fans.

👉 Partner with MEGA FANS to transform your cooling challenges into competitive advantages.

📩 Contact Us:

Email: inquiry@cnmegatech.com

🌐 Website: www.cnmegatech.com / www.megacoolingsolution.com

Articles you may also like:

MEGA’s IP68 Cooling Fans for Gobo and LED Projector Thermal Management

Why EV Charger Cooling Fans Are Essential for Performance and Cost Savings

Streamline Your Thermal Design: One Supplier for Fans and Heat Sinks

MEGA Tech 4010 DC Fan with Forward & Reverse Rotation

MEGA Boosts Performance and Cuts Costs with Custom DC Fan Replacements