IP Rating introduction

Usually, the waterproof cooling fan on the market refers to the cooling fan with protection level IP53 and above. Normally the protection level basically does not exceed IP56, because, excluding foreign manufacturers, there are only a few domestic manufacturers who have the technical ability to achieve IP68 protection for cooling fans. We, Mega Tech, are proud of being one of them,Our DC fans can undergo a rigorous vacuum sealing process, enabling them to operate during submersion. Here we will briefly introduce the knowledge of IP protection level as follows.

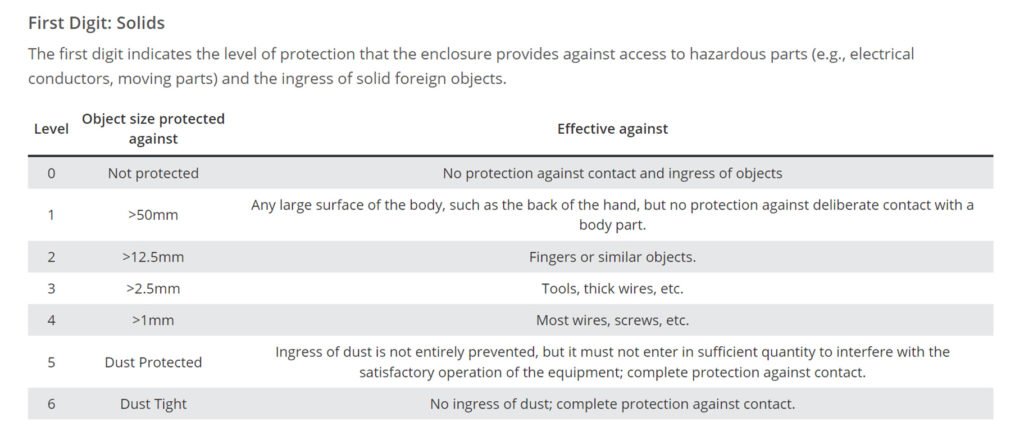

IP Rating Solids

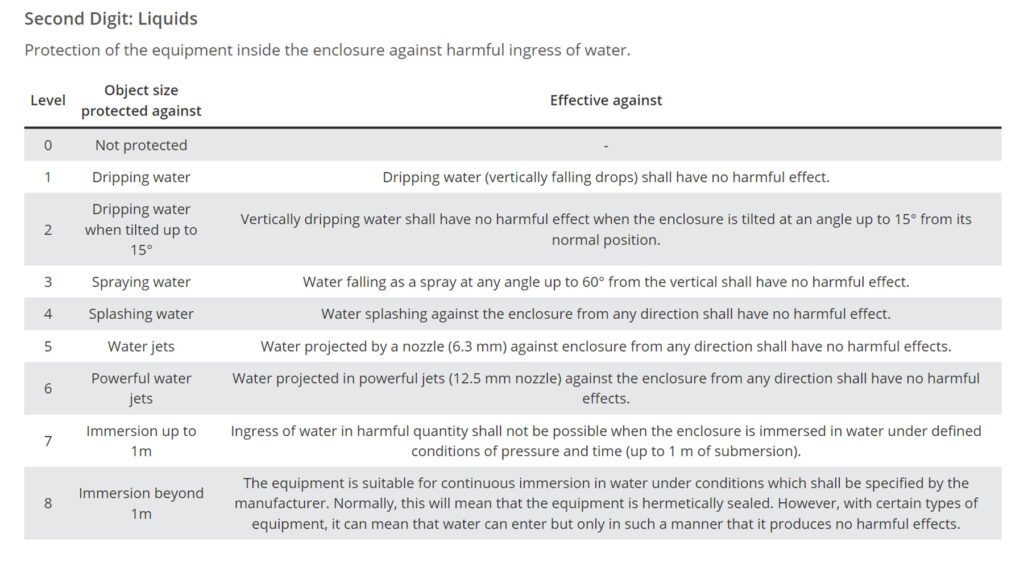

IP Rating liquids

What is waterproof axial flow fans?

Generally, we believe that the waterproof fan is divided into IP55 and IP68. The waterproof fan or waterproof motor with IP55 waterproof rating has only moisture-proof function. The manufacturing method generally uses the three-proof paint on the outer surface of the motor, which has the ability of publication oxidation.

IP68 waterproof fans are generally manufactured by vacuum coating or epoxy filling.

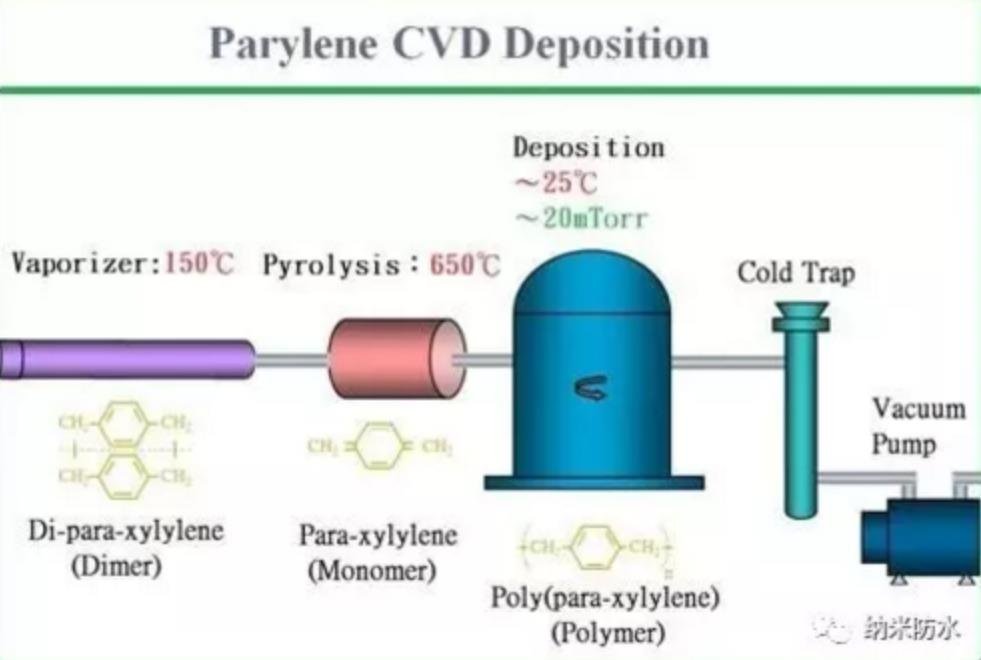

Frist, Vacuum coating

The vacuum coating process is similar to semiconductor lithography. In a vacuum environment, atoms of the material are separated from the heating source . The material is plasticized on the surface of the object to be coated. It is also injected into the metal motor body and a layer of nanomaterial is deposited on the surface of the object. The thickness of the film layer is typically 5 to 30 microns. The electroplating process has advantages such as good heat dissipation efficiency and rapid batch manufacturing. However, nanomaterials are generally not resistant to corrosion. The film layer will peel off over time.

Second,Epoxy Resin filling

For the high requirements of waterproof products, even the requirements of the possibility of soaking in water, which is required to isolate the entire motor, so that water can not interfere with the motor, a more reliable practice is PCB plus epoxy resin. seal the motor, that can not see the motor. In the motor internal glue protects the important heart of the fan. At the same time, the fan rotor, and metal frame leaves for anti-rust treatment, so as to ensure that the fan can be dustproof, waterproof, and anti-corrosion so that it can adapt to a variety of working environments.

Comparison

The epoxy resin-sealed waterproof fan can resist corrosion, and this kind of waterproof fan needs a special mold to add waterproof function, the internal structure is well designed to do gluing, and the motor adds a special mold to protect the cover. It is also necessary to have a special mold to be able to. To do this process is to put the waterproof fan in the water work, which also does not affect the performance of the fan. Therefore, the effect of sealing the motor by grouting resin is better and makes the process more responsible, but the production speed is slower, the center motor cooling effect is a little worse, and the price is more expensive than the coating process.

The IP68 rating is important to ensure that the electronics inside the enclosure have the highest level of protection against foreign objects and water, while also protecting the user from potentially harmful exposure. Equipment installed outdoors faces high temperatures and cold, wind and sun, and other harsh weather corrosion and rust, cooling fans play a role in cooling the equipment under difficult conditions. IP68 series fans, can comfortably cope with a variety of working conditions of long-term stable work, to protect the normal operation of equipment.

Mega Tech Waterproof Cooling Fan

As a cooling fan manufacturer, and a supplier of many kinds of fan products from Germany, America, Italy and Japan. We have been committed to providing product solutions that satisfy our customers, and our company has a large inventory for a long time, which greatly shortens the delivery time, reduces customers’ operating costs and improves work efficiency.

If you are looking for an IP68 fan, then choose Mega Tech! We are supported by our own professional R&D team with rich experience in the field of cooling. Since the establishment of our company, our business has been growing steadily. Our main business focuses on modular design of DC cooling fans covering different products such as computer, power supply, communication, home appliance and auto parts, as well as OEM/ODM collaborative system manufacturing. The company has been authorized and strictly follows ISO9001 and IATF16949 system management, and the products have passed SGS/UL/CE and other international certifications. If you need, please feel free to consult us.

More information

Not only does Mega offer customized waterproof solutions, but it also provides perfect alternatives to well-known brands like EBM, Sanyo Denki, and Sunon. Our fans are designed to meet or exceed the performance of these renowned brands, ensuring reliable and efficient cooling solutions for various applications. With Mega’s quality and performance, you can confidently replace your existing fans with our superior products.

Articles you may also like:

China’s Best EBM Papst Cooling Fan Alternatives

EBM 6314/2 TDHP Alternatives- MEGE 17251 Axial Fan