Main Menu

3200RPM 120X120X38mm 12038 AC120V AC220V Industrial air Conditioner Fan Ventilation AC Axial Cooling Fan

Category AC Axial Fan

Tag 12038 AC brushless fan

This 120x120x38mm AC brushless fan produced by Guangzhou Mega Technology Co., Ltd. This AC brushless fan is a rugged and versatile cooling solution. Its ball bearing design promises long life, while the aluminum alloy frame and blade construction represent durability and efficient cooling performance. The fan has good air volume and static pressure capabilities, making it suitable for applications where effective heat dissipation is required and space allows for a 120x120x38mm fan. Available in 110V and 220V models, it can adapt to different power supply environments. The noise level is within reasonable range for industrial or electronic equipment cooling.

Parameter Value

Product Type: AC brushless fan

- Size: 120x120x38mm

- Bearing Type: ball、Sleeve

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:535g

- Rated Voltage: 110V,220V

- Rated Current: 0.13/0.11A(110V);0.06/0.08A(220V);

- Rated Input Power:12/21W

- Speed:2750/3200RPM

- Air Flow:105/123CFM

- Maximum Air Pressure:7.1/8.9mH2O

- Noise Level:47/49dB-A

Additional information

For other products not shown on website, please contact our team.

inquiry@cnmegatech.com

Product Details:

This 120x120x38mm AC brushless fan produced by Guangzhou Mega Technology Co., Ltd. This AC brushless fan is a rugged and versatile cooling solution. Its ball bearing design promises long life, while the aluminum alloy frame and blade construction represent durability and efficient cooling performance. The fan has good air volume and static pressure capabilities, making it suitable for applications where effective heat dissipation is required and space allows for a 120x120x38mm fan. Available in 110V and 220V models, it can adapt to different power supply environments. The noise level is within reasonable range for industrial or electronic equipment cooling.

Parameter Value

Product Type: AC brushless fan

- Size: 120x120x38mm

- Bearing Type: ball、Sleeve

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:535g

- Rated Voltage: 110V,220V

- Rated Current: 0.13/0.11A(110V);0.06/0.08A(220V);

- Rated Input Power:12/21W

- Speed:2750/3200RPM

- Air Flow:105/123CFM

- Maximum Air Pressure:7.1/8.9mH2O

- Noise Level:47/49dB-A

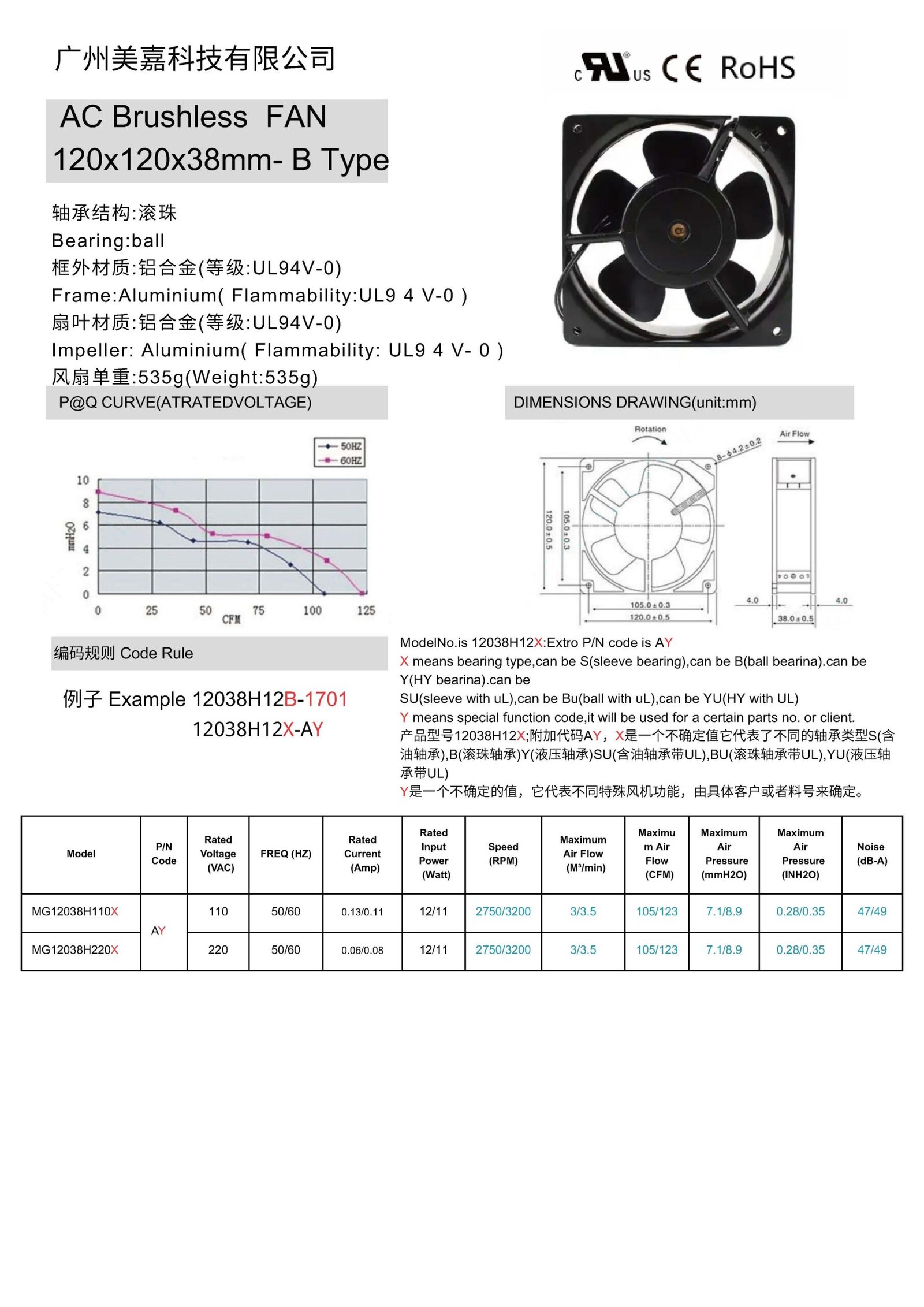

| Model | Rated Voltage (VAC) | FREQ (HZ) | Rated Current (Amp) | Rated Input Power (Watt) | Speed (RPM) | Maximum Air Flow (CFM) | Max. Static Pressure (mmH2O) | Noise (DB-A) |

| MG12038H110X | 110 | 50/60 | 0.13/0.11 | 12月11日 | 2750/3200 | 105/123 | 7.1/8.9 | 47/49 |

| MG12038H220X | 220 | 50/60 | 0.06/0.05 | 12月11日 | 2750/3200 | 105/123 | 7.1/8.9 | 47/49 |

Key Features and Advantages:

Main Features:

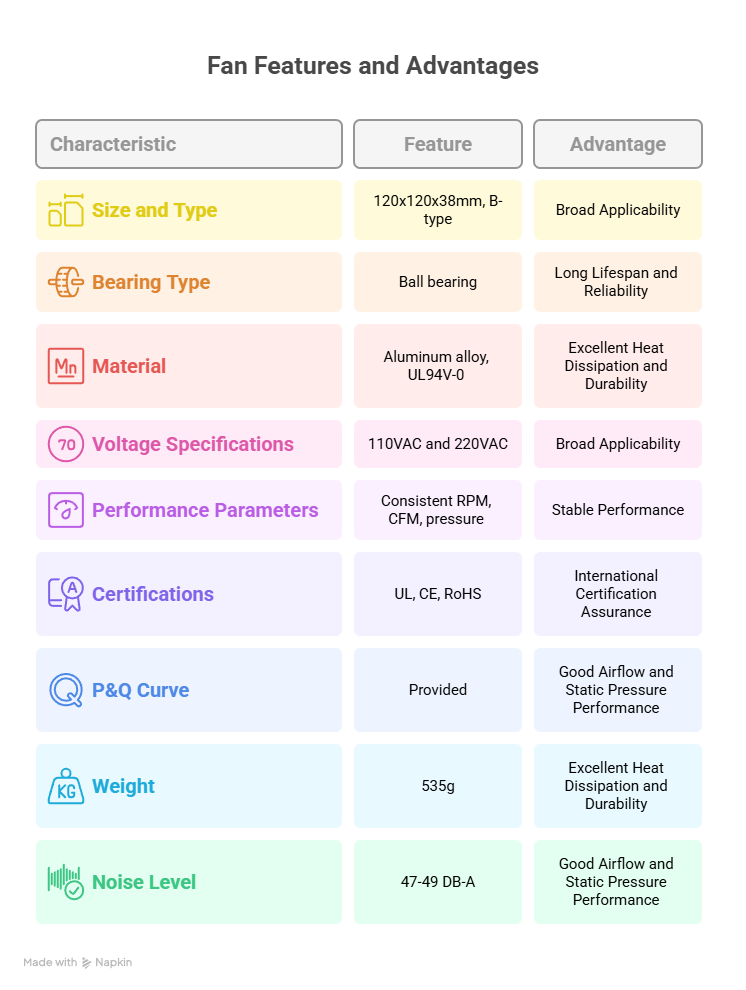

1. Size and Type: A standard 120x120x38mm AC brushless fan, classified as B-type. This is a common standard size in industrial and electronic equipment, facilitating compatibility and replacement.

2. Bearing Type: Employs a ball bearing design. This is one of its crucial mechanical characteristics.

3. Material: Both the frame and impeller are made of aluminum alloy, with a flame retardancy rating of UL94V-0.

4. Diverse Performance Parameters: Offers both 110VAC and 220VAC voltage specifications. Under different voltages, it maintains similar rotational speeds (2750/3200 RPM), airflow (105/123 CFM), and static pressure (7.1/8.9 mmH2O).

5. Certifications: Possesses multiple international certifications, including UL, CE, and RoHS, indicating compliance with relevant safety, health, and environmental standards.

6. P&Q Curve: Provides a pressure-quantity (P-Q) curve graph, visually demonstrating its performance under different loads.

7. Weight: Each fan weighs 535g, which is relatively heavy, likely due to the all-aluminum alloy construction.

8. Noise Level: The noise range is between 47-49 DB-A.

Main Advantages:

1. Long Lifespan and Reliability: The use of ball bearings is one of its most significant advantages. Compared to sleeve bearings, ball bearings offer a longer service life, better high-temperature resistance, and higher reliability, especially suitable for equipment requiring continuous long-term operation.

2. Excellent Heat Dissipation and Durability: The all-aluminum alloy (frame and impeller) construction ensures the fan’s structural rigidity and resistance to deformation. Aluminum alloy itself has excellent thermal conductivity, which helps dissipate heat from the fan itself, further enhancing its stability and lifespan. The UL94V-0 flame retardancy rating also adds to the product’s safety.

3. Broad Applicability:

o Its standard size makes it easy to integrate into various equipment and chassis.

o The availability of both 110V and 220V voltage specifications allows it to adapt to different power standards worldwide, greatly expanding its range of applications.

4. Stable Performance: As seen from the specification table, despite different voltages, the fan maintains consistent performance in key indicators such as rotational speed, airflow, and static pressure. This indicates that its design provides stable cooling performance across different power environments.

5. International Certification Assurance: Having UL, CE, and RoHS certifications means the product meets international market access requirements, guaranteeing quality and giving users more confidence in purchasing and use. This is particularly important for export and international projects.

6. Good Airflow and Static Pressure Performance: An airflow of 105-123 CFM and static pressure of 7.1-8.9 mmH2O for a 120x120x38mm fan provide good air movement and the ability to overcome resistance, effectively meeting the cooling needs of most equipment.

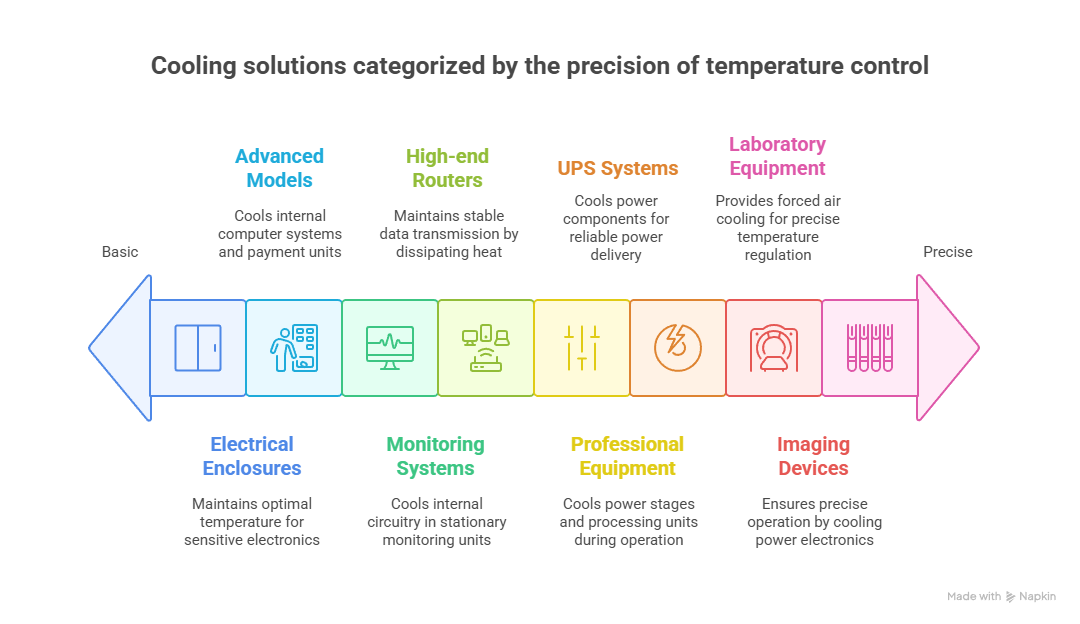

Applications

- Industrial Control and Automation Equipment:

- Industrial PCs (IPCs) and Servers: Used to cool CPUs, GPUs, and other heat-generating components within robust industrial computer systems that operate in harsh environments.

- Programmable Logic Controllers (PLCs) Cabinets: Provides internal airflow to dissipate heat generated by PLC modules, power supplies, and other control components in automation systems.

- Variable Frequency Drives (VFDs) / Motor Drivers: Essential for cooling the power semiconductors (IGBTs, MOSFETs) within VFDs, which generate significant heat during operation to control motor speed.

- Industrial Power Supplies and Converters: Used to cool transformers, rectifiers, and other power components in industrial-grade power supply units, ensuring stable voltage output.

- Control Cabinets/Electrical Enclosures: Installed on cabinet doors or inside to maintain an optimal operating temperature for sensitive electronic components, preventing overheating and extending equipment life. This could include cabinets for robotics, manufacturing lines, or process control.

- Telecommunications and Networking Equipment:

- Network Servers (Rackmount/Tower): Provides cooling for processors, hard drives, and network interface cards in data centers and server rooms to prevent overheating and ensure continuous data flow.

- Telecommunications Base Stations: Used to cool power amplifiers, transceivers, and other electronic modules in cellular base stations, which often operate outdoors under varying temperature conditions.

- Network Switches and Routers (High-end/Enterprise-grade): Dissipates heat from integrated circuits and power components in high-performance networking devices to maintain stable data transmission.

- Cabinet Cooling for Communication Systems: Integrated into outdoor communication cabinets or shelters to regulate internal temperature and protect sensitive equipment from environmental heat.

- Medical Equipment:

- Medical Imaging Devices (e.g., MRI, CT Scanners, X-ray Machines): Critical for cooling the power electronics, control boards, and often the X-ray tubes (indirectly, through cooling surrounding components) to ensure precise and safe operation.

- Laboratory Equipment (e.g., Blood Analyzers, DNA Sequencers, Incubators): Provides forced air cooling for internal electronics, temperature control systems, or sample compartments that require precise temperature regulation.

- Patient Monitoring Systems: Used in larger, stationary patient monitors or central monitoring units to cool their internal circuitry.

- Commercial and Professional Equipment:

- Large Format Printers/Plotters: Dissipates heat from print heads, control boards, and drying systems in high-volume or specialized printing equipment.

- Professional Audio/Video Equipment (e.g., High-power Amplifiers, Broadcast Transmitters): Essential for cooling power stages and processing units that generate substantial heat during continuous operation.

- Vending Machines / Kiosks (Advanced Models): Provides cooling for internal computer systems, touchscreens, and payment processing units, especially in models with more complex electronics or outdoor installations.

- Security and Surveillance Systems (DVR/NVR Enclosures): Cools the hard drives and processing units in digital/network video recorders to ensure reliable continuous recording and playback.

- Other Specialized Applications:

- Power Generation and Distribution (e.g., UPS Systems, Rectifiers): Used in large Uninterruptible Power Supply (UPS) units, battery chargers, and rectifiers to cool power components and ensure reliable power delivery.

- Electric Vehicle (EV) Charging Stations: Provides cooling for the power conversion modules within high-power EV fast-charging stations.

- Heating, Ventilation, and Air Conditioning (HVAC) Systems (Specific Components): Could be used for localized cooling of control panels, motor drivers, or sensitive sensors within larger HVAC units.

Our advantage

Guangzhou Mega Technology Co., Ltd. is located in Guangzhou, Guangdong Province. We benchmark against leading cooling fan manufacturers like Delta Electronics, Nidec Corporation, Sunon, Sanyo Denki, and Orion Fans. Offering AC, DC, and EC fans, we provide customized cooling solutions for various industrial and commercial applications. Our strong R&D and technical expertise ensure our products match top manufacturers’ performance at significantly lower prices.

We pride ourselves on delivering tailored solutions to meet unique client needs. Our team collaborates closely with customers to design products that optimize cooling performance, energy efficiency, and reliability. Whether for electronic devices, industrial machinery, or commercial systems, Guangzhou Mega Technology Co., Ltd. is dedicated to providing high-quality, cost-effective solutions that exceed expectations. Our commitment to innovation and customer satisfaction keeps us at the forefront of the cooling fan industry.

Reasons to Choose Us

- Factory Direct Sales, Preferential Price: We are the manufacturer, eliminating intermediate links, and providing you with the most competitive price.

- Quality Assurance, Worry-Free After-Sales: We provide perfect after-sales service, so you can buy without worry.

- Professional Team, Customized Service: We have a professional R & D team to provide you with customized solutions.

Related products

-

2700/3200RPM AC Fan 80 X80x38mm AC Axial Flow Fan Ball Bearing Back High Speed Cooling Radiator

Read more -

80x80x38mm 8038 Ac Cooling Fan 80mm 110v 220V AC brushless Axial Fan

Read more -

110V 220V 380V 15050 150x150x50mm Ac Cooling Fan

Read more -

172 x 150 x 38 mm AC Axial Fan

Read more -

120 x 120 x 25 mm AC Axial Fan

Read more