Main Menu

24V 12V 60mm 6015 Turbo blower Cooling fan 60x60x15mm Blower Fan

Category Blower

Tag 6015 DC brushless blower fan

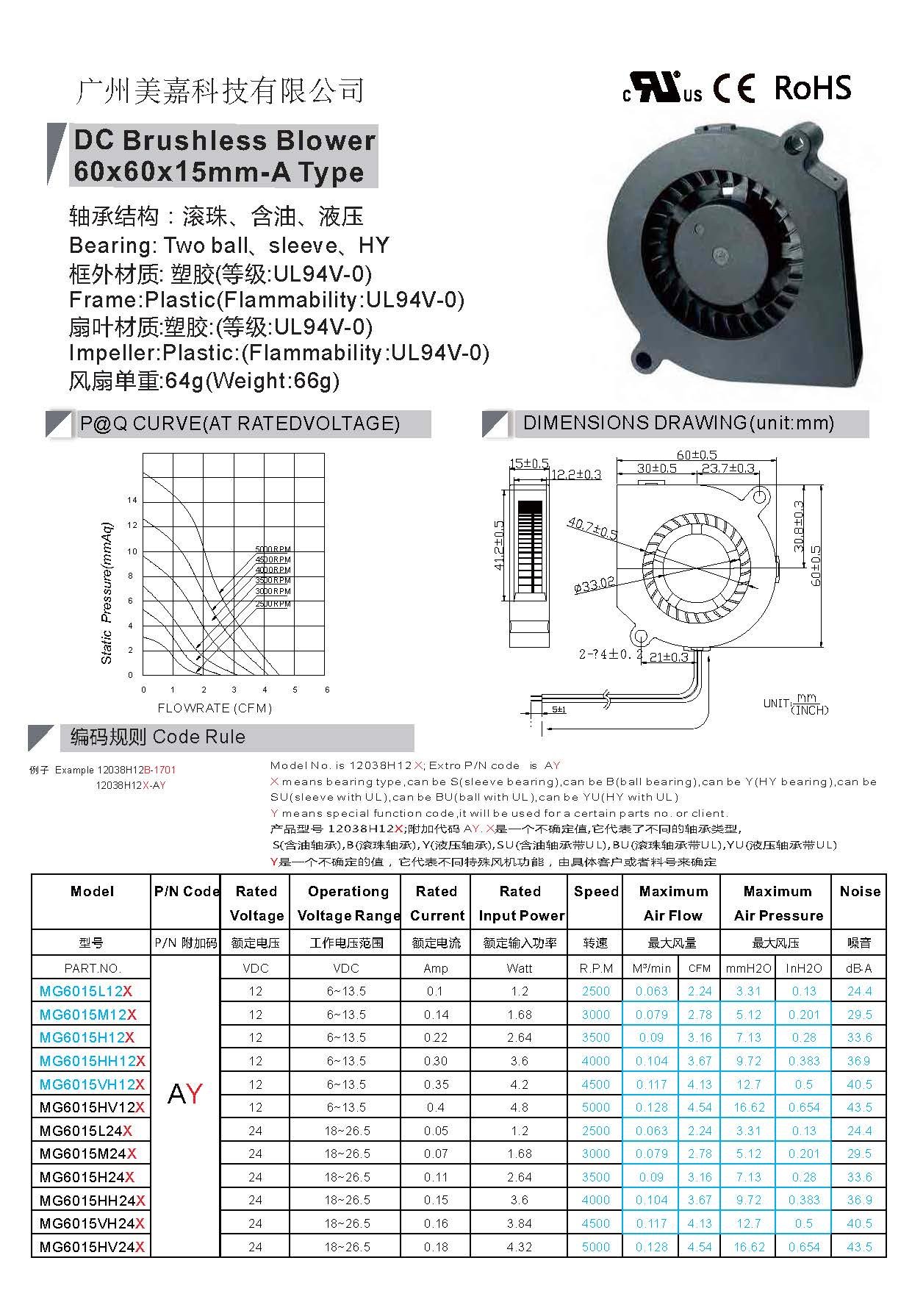

This is a 60x60x15mm-A DC brushless blower produced by Guangzhou Mega Technology Co., Ltd. It provides models with a variety of bearing types (ball, oil-containing, hydraulic) and two rated voltages of 12V/24V. Its outer frame and fan blades are made of UL94V-0 grade flame-retardant plastic.

Parameter Value

Product Type: DC brushless blower fan

- Size: 60x60x15mm

- Bearing Type: Bearing、sleeve、HY

- Frame Material: Plastic (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:64g

- Rated Voltage: 12V,24V

- Voltage Range:6-13.5V(12V);18-26.5(24V)

- Rated Current:0.05-0.4A

- Rated Input Power:1.2-4.32W

- Speed:2500-5000RPM

- Air Flow:2.24-4.54CFM

- Maximum Air Pressure:3.31-16.62mH2O

- Noise Level:24.4-43.5dB-A

Additional information

For other products not shown on website, please contact our team.

inquiry@cnmegatech.com

Product Details:

This is a 60x60x15mm-A DC brushless blower produced by Guangzhou Mega Technology Co., Ltd. It provides models with a variety of bearing types (ball, oil-containing, hydraulic) and two rated voltages of 12V/24V. Its outer frame and fan blades are made of UL94V-0 grade flame-retardant plastic.

Parameter Value

Product Type: DC brushless blower fan

- Size: 60x60x15mm

- Bearing Type: Bearing、sleeve、HY

- Frame Material: Plastic (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:64g

- Rated Voltage: 12V,24V

- Voltage Range:6-13.5V(12V);18-26.5(24V)

- Rated Current:0.05-0.4A

- Rated Input Power:1.2-4.32W

- Speed:2500-5000RPM

- Air Flow:2.24-4.54CFM

- Maximum Air Pressure:3.31-16.62mH2O

- Noise Level:24.4-43.5dB-A

| Model | Rated Voltage | Operationg Voltage Range | Rated Current | Rated Input Power | Speed | Maximum Air Flow | Maximum Air Pressure | Noise |

| PART.NO. | VDC | VDC | Amp | Watt | R.P.M | CFM | mmH2O | dB-A |

| MG6015L12X | 12 | 6~13.5 | 0.1 | 1.2 | 2500 | 2.24 | 3.31 | 24.4 |

| MG6015M12X | 12 | 6~13.5 | 0.14 | 1.68 | 3000 | 2.78 | 5.12 | 29.5 |

| MG6015H12X | 12 | 6~13.5 | 0.22 | 2.64 | 3500 | 3.16 | 7.13 | 33.6 |

| MG6015HH12X | 12 | 6~13.5 | 0.3 | 3.6 | 4000 | 3.67 | 9.72 | 36.9 |

| MG6015VH12X | 12 | 6~13.5 | 0.35 | 4.2 | 4500 | 4.13 | 12.7 | 40.5 |

| MG6015HV12X | 12 | 6~13.5 | 0.4 | 4.8 | 5000 | 4.54 | 16.62 | 43.5 |

| MG6015L24X | 24 | 18~26.5 | 0.05 | 1.2 | 2500 | 2.24 | 3.31 | 24.4 |

| MG6015M24X | 24 | 18~26.5 | 0.07 | 1.68 | 3000 | 2.78 | 5.12 | 29.5 |

| MG6015H24X | 24 | 18~26.5 | 0.11 | 2.64 | 3500 | 3.16 | 7.13 | 33.6 |

| MG6015HH24X | 24 | 18~26.5 | 0.15 | 3.6 | 4000 | 3.67 | 9.72 | 36.9 |

| MG6015VH24X | 24 | 18~26.5 | 0.16 | 3.84 | 4500 | 4.13 | 12.7 | 40.5 |

| MG6015HV24X | 24 | 18~26.5 | 0.18 | 4.32 | 5000 | 4.54 | 16.62 | 43.5 |

Key Features and Advantages:

Main Features:

- Compact size: The 60x60x15mm dimensions make it ideal for space-constrained applications and easy to integrate into small devices.

- Multiple bearing types available: Three types of bearings are offered: Two ball, sleeve, and HY (hydraulic), to meet the different needs of various application scenarios for lifespan, noise, and cost.

- Flame-retardant materials: Both the frame and impeller are made of UL94V-0 grade flame-retardant plastic, improving product safety.

- Two rated voltages: Offers two rated voltages of 12V and 24V, increasing the product’s applicability.

- Detailed performance parameters: The image provides a flow rate-static pressure curve (P@Q Curve) and a detailed parameter table, including rated current, input power, speed, maximum airflow, maximum air pressure, and noise information, which is convenient for users to select models and design.

- DC brushless motor: Uses a DC brushless motor, which has the advantages of high efficiency, long life, and low noise.

Main Advantages:

- Flexibility and adaptability: Multiple bearing types, two rated voltages, and a rich selection of performance parameters enable this series of fans to adapt to various application scenarios and needs. Users can choose the appropriate model according to specific needs. For example, those with high life requirements can choose ball bearings, and those sensitive to cost can choose sleeve bearings.

- High safety: The use of UL94V-0 grade flame-retardant materials effectively reduces fire risks and improves product safety. This is especially important in applications with high safety requirements, such as medical equipment and industrial control equipment.

- High efficiency and energy saving: Compared with traditional brushed motors, DC brushless motors have higher efficiency, which can effectively reduce energy consumption and save energy.

- Long life and low maintenance: DC brushless motors do not require replacement of brushes, reducing maintenance workload, extending product lifespan, and reducing user maintenance costs.

- Low noise operation: DC brushless motors have lower operating noise, which can provide a quieter working environment. This is very important in applications sensitive to noise, such as household appliances and medical equipment.

- Excellent heat dissipation performance: Through optimized impeller design and motor performance, this series of fans can provide good heat dissipation, effectively reducing the operating temperature of equipment and improving the reliability and stability of the equipment.

- Comprehensive technical support: Guangzhou Mega Technology Co., Ltd., as a professional fan manufacturer, can provide comprehensive technical support and after-sales service to help users solve problems encountered in applications.

Applications

- Heat dissipation of small electronic devices:

- Routers and modems: Used to dissipate heat from chipsets, processors, and other heating elements to maintain stable operation of the device and prolong its service life. For example, home wireless routers, optical modems, etc.

- Network switches and hubs: Used to dissipate heat from switching chips and power modules to ensure the reliability and performance of network equipment. For example, desktop switches, small enterprise-level switches, etc.

- Set-top boxes and media players: Used to dissipate heat from processors, graphics chips, and other integrated circuits to prevent overheating from causing crashes or performance degradation. For example, network TV boxes, high-definition media players, etc.

- Portable electronic devices: For example, small projectors, VR/AR devices, portable printers, etc. These devices have limited space and require efficient heat dissipation solutions.

- Solid State Drive (SSD) heat dissipation: Some high-performance M.2 solid-state drives generate a lot of heat during high-speed reading and writing. Using this small fan can assist in heat dissipation and improve the stability and lifespan of the SSD.

- Heat dissipation of industrial control equipment:

- Programmable Logic Controller (PLC): Used to dissipate heat from CPUs, memory, and other modules to ensure stable and reliable operation of the PLC in industrial environments.

- Frequency converters and servo drives: Used to dissipate heat from power modules and control circuits to prevent equipment failure due to overheating.

- Industrial computers and embedded systems: Used to dissipate heat from processors, chipsets, and other key components to ensure the system works normally in harsh environments. For example, industrial computers, industrial tablet PCs, etc.

- Numerical Control Machine Tool (CNC) control system: Used to dissipate heat from electronic components in the control cabinet to ensure the processing accuracy and stability of CNC machine tools.

- Medical equipment:

- Medical monitors: Used to dissipate heat from processors, display drivers, and other electronic components to ensure the accuracy and reliability of the monitors.

- Ventilators and anesthesia machines: Used to dissipate heat from motors, sensors, and other key components to ensure the normal operation of the equipment and patient safety.

- Analytical instruments: For example, blood analyzers, biochemical analyzers, etc., used to dissipate heat from light sources, detectors, and other electronic components to improve the accuracy of analysis results.

- Small medical devices: For example, portable blood pressure monitors, blood glucose meters, etc., used to dissipate heat from internal circuits and extend the service life of the devices.

- Automotive electronics:

- Car navigation and entertainment systems: Used to dissipate heat from processors, displays, and other electronic components to ensure the system works normally in the high-temperature environment inside the car.

- Automotive Electronic Control Unit (ECU): For example, engine control units, braking control units, etc., used to dissipate heat from internal circuits and improve the reliability of automotive electronic systems.

- LED car light heat dissipation: Some high-power LED car lights also require small fans to assist in heat dissipation to ensure the brightness and lifespan of the LEDs.

- Home appliances:

- Air purifiers and humidifiers: Used to promote air circulation and dissipate heat from motors to improve purification and humidification efficiency.

- Vacuum cleaners and sweeping robots: Used to dissipate heat from motors and control circuits to ensure the normal operation of the machines.

- Smart toilet lids: Some high-end smart toilet lids have heating and drying functions, which require small fans for heat dissipation.

- Projectors: Used to dissipate heat from bulbs and optical components to prevent overheating from affecting the projection effect and equipment lifespan.

- Other applications:

- LED lighting: Some high-brightness LED lamps require cooling fans to maintain their operating temperature to ensure brightness and lifespan.

- 3D printers: Used to dissipate heat from extruders, stepper motors, and other heating elements to improve printing quality and stability.

- Servers and Network Attached Storage (NAS) devices: Although 60x60mm fans are usually not used in large servers, they may be used for auxiliary heat dissipation in some small servers or NAS devices.

Our advantage

Guangzhou Mega Technology Co., Ltd. is located in Guangzhou, Guangdong Province. We benchmark against leading cooling fan manufacturers like Delta Electronics, Nidec Corporation, Sunon, Sanyo Denki, and Orion Fans. Offering AC, DC, and EC fans, we provide customized cooling solutions for various industrial and commercial applications. Our strong R&D and technical expertise ensure our products match top manufacturers’ performance at significantly lower prices.

We pride ourselves on delivering tailored solutions to meet unique client needs. Our team collaborates closely with customers to design products that optimize cooling performance, energy efficiency, and reliability. Whether for electronic devices, industrial machinery, or commercial systems, Guangzhou Mega Technology Co., Ltd. is dedicated to providing high-quality, cost-effective solutions that exceed expectations. Our commitment to innovation and customer satisfaction keeps us at the forefront of the cooling fan industry.