Main Menu

20572 110V 220V Premium Brushless Axial Heat Sink Solar Inverter Cooling Fan

Category AC Axial Fan

Tag 20572 AC brushless fan

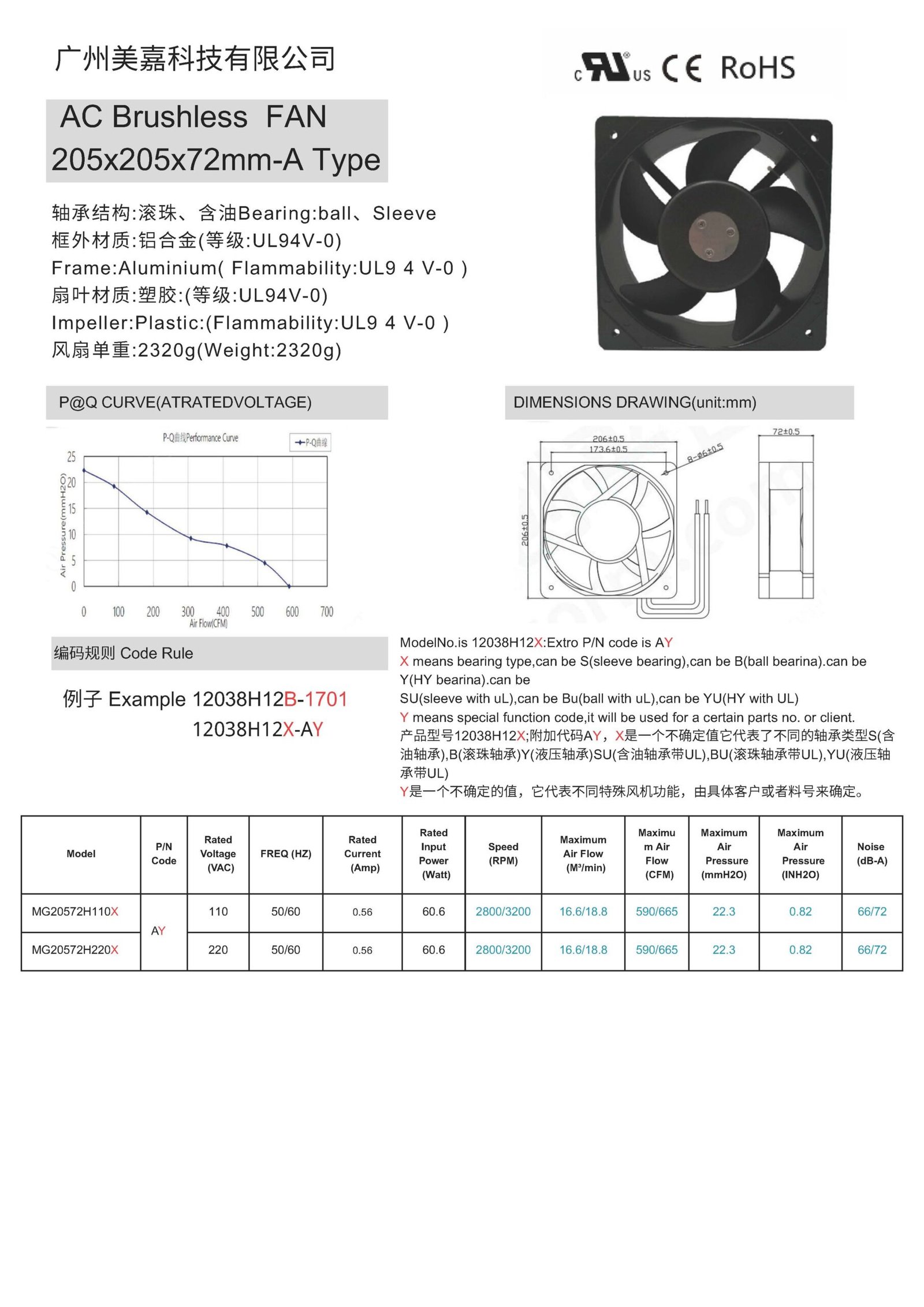

This 205x205x72mm AC brushless fan produced by Guangzhou Mega Technology Co., Ltd. is a high-performance industrial-grade cooling/ventilation device. It uses a sturdy aluminum frame and flame-retardant plastic blades, provides a variety of options such as ball bearings or sleeve bearings, and has multiple certifications such as CE, UL, RoHS, etc. The fan has high air volume (up to 590-665 CFM) and high static pressure (up to 22.3 mmH2O), and is available in 110V and 220V rated voltage models, both of which are consistent in main performance parameters. The operating noise (66-72 dB-A) is in line with the characteristics of its industrial application scenarios. The product model coding system is clear, which is convenient for customers to choose according to the bearing type and specific functional requirements.

Parameter Value

Product Type: AC brushless fan

- Size: 205x205x72mm

- Bearing Type: ball

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:2320g

- Rated Voltage: 110V,220V

- Rated Current: 0.56A;

- Rated Input Power:60.6W;

- Speed:2800/3200RPM

- Air Flow:590/665CFM

- Maximum Air Pressure:22.3mH2O

- Noise Level:66/72dB-A

Additional information

For other products not shown on website, please contact our team.

inquiry@cnmegatech.com

Product Details:

This 205x205x72mm AC brushless fan produced by Guangzhou Mega Technology Co., Ltd. is a high-performance industrial-grade cooling/ventilation device. It uses a sturdy aluminum frame and flame-retardant plastic blades, provides a variety of options such as ball bearings or sleeve bearings, and has multiple certifications such as CE, UL, RoHS, etc. The fan has high air volume (up to 590-665 CFM) and high static pressure (up to 22.3 mmH2O), and is available in 110V and 220V rated voltage models, both of which are consistent in main performance parameters. The operating noise (66-72 dB-A) is in line with the characteristics of its industrial application scenarios. The product model coding system is clear, which is convenient for customers to choose according to the bearing type and specific functional requirements.

Parameter Value

Product Type: AC brushless fan

- Size: 205x205x72mm

- Bearing Type: ball

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:2320g

- Rated Voltage: 110V,220V

- Rated Current: 0.56A;

- Rated Input Power:60.6W;

- Speed:2800/3200RPM

- Air Flow:590/665CFM

- Maximum Air Pressure:22.3mH2O

- Noise Level:66/72dB-A

| Model | Rated Voltage (VAC) | FREQ (HZ) | Rated Current (Amp) | Rated Input Power (Watt) | Speed (RPM) | Maximum Air Flow (CFM) | Maximum Air Pressure (mmH2O) | Noise (dB-A) |

| MG20572H110X | 110 | 50/60 | 0.56 | 60.6 | 2800/3200 | 590/665 | 22.3 | 66/72 |

| MG20572H220X | 220 | 50/60 | 0.56 | 60.6 | 2800/3200 | 590/665 | 22.3 | 66/72 |

Key Features and Advantages:

Main Characteristics:

1. Size and Type: Standard large size of 205x205x72mm, categorized as an A-type AC brushless fan, suitable for applications requiring significant airflow and cooling space.

2. Material and Flame Retardancy: Constructed with an aluminum frame and plastic impellers, both materials boast a UL94V-0 flame retardancy rating. This enhances product safety and reliability, especially in environments potentially exposed to high temperatures or fire risks.

3. Multiple Bearing Type Options: Offers a choice of two fundamental bearing structures: ball bearing and sleeve bearing, alongside UL-certified HY, sleeve, and ball bearing options. This caters to diverse customer preferences regarding lifespan, noise levels, and cost.

4. Wide Voltage Compatibility: Available in both 110V and 220V rated voltage versions (MG20572H110X and MG20572H220X). Crucially, the performance parameters (current, power, speed, airflow, static pressure, noise) remain largely consistent for both voltage versions at 50/60Hz, facilitating global usability across different voltage environments.

5. High Performance Parameters: Exhibits high rotational speed (2800/3200 RPM), large airflow (max 590/665 CFM or 16.6/18.8 M3/Min), and high static pressure (max 22.3 mmH2O or 0.82 IN H2O), providing robust cooling or ventilation capabilities.

6. Intuitive P-Q Curve Display: Includes a fan performance curve (Airflow-Static Pressure) graph, which visually represents the fan’s performance at various operating points, aiding in user evaluation and selection.

7. Detailed Code Rule: The clear coding rule precisely defines the meaning of each part of the model number (e.g., “X” for bearing type and special function code), enabling accurate product identification and customization.

Main Advantages:

1. High Reliability and Safety: The use of an aluminum frame, UL94V-0 flame-retardant materials, and multiple international certifications like UL, CE, and RoHS, ensures the product’s quality, safety, and environmental compliance, making it competitive in the global market.

2. Strong Versatility: The standard 205x205x72mm dimensions allow for easy integration into various equipment and systems. Furthermore, offering two main voltage versions enables adaptation to different power standards across countries and regions, broadening its market application scope.

3. Powerful Cooling Capability: The high airflow and static pressure characteristics make this fan highly suitable for demanding cooling applications in industrial equipment, telecommunications devices, power supply systems, control cabinets, and more.

4. Customization Potential: The clear coding rule, particularly the presence of a “Y” for special function codes, indicates the product’s capacity for customization. It can be tailored to specific customer requirements (e.g., special functions, customer part numbers), enhancing its flexibility and market adaptability.

5. Stable Performance: As evident from the specifications table, the consistent performance parameters across different voltage versions suggest a high degree of maturity and stability in the product’s design and manufacturing.

Applications

1. Telecommunications Equipment and Data Centers:

a) Application Scenarios: High-power telecommunication base stations, data center server racks, network switches, routers, etc. These devices have extremely high internal heat density and require continuous, efficient cooling to ensure stable operation.

b) Specific Equipment:

i. Telecom Base Stations/Equipment Rooms: Used for ventilation and heat dissipation to ensure stable operation of communication modules, power modules, etc., in high-temperature environments.

ii. Server Racks/Blade Servers: Act as exhaust/intake fans at the rear or top of the rack to create effective cooling channels, removing heat generated by servers.

iii. Large Network Switches/Routers: Integrated internally to provide forced convection cooling for high-performance chips and power modules.

iv. UPS Power Systems: Provide heat dissipation for power conversion modules, battery packs, and other components in high-power uninterruptible power supply equipment.

2. Industrial Automation Equipment:

a) Application Scenarios: Internal heat dissipation for various industrial control cabinets, inverters, servo drives, welding equipment, injection molding machines, and other large industrial machinery. These devices often operate in harsh environments, generate significant heat, and demand extremely high stability and reliability.

b) Specific Equipment:

i. PLC Control Cabinets/Electrical Cabinets: Serve as the primary fan for internal ventilation and heat dissipation, preventing overheating and failure of internal components.

ii. Inverters/Servo Drives: Directly installed inside the equipment to cool high-heat-generating components like IGBT modules and rectifier bridges.

iii. Industrial Power Supplies/Distribution Cabinets: Ensure the operating temperature of power modules and circuit boards remains within permissible limits.

iv. Industrial Robot Control Boxes: Provide cooling for the complex control systems inside robots.

3. Medical Imaging Equipment:

1. Application Scenarios: Large medical diagnostic equipment such as CT scanners, MRI machines, X-ray machines. These devices operate for long periods, and their internal high-precision electronic components generate substantial heat, requiring highly stable and continuous heat dissipation.

2. Specific Equipment:

i. Mainframe/Control Units of CT/MRI Equipment: Internal cooling to ensure imaging accuracy and equipment lifespan.

ii. X-ray Machine High-Voltage Generators: Cool high-voltage components to ensure safe and stable operation.

4. New Energy Equipment:

a) Application Scenarios: Wind power converters, solar inverters, electric vehicle charging stations, etc. These devices handle high-power currents, generating considerable heat, and require efficient dissipation to maintain efficiency and safety.

b) Specific Equipment:

i. Wind Turbine Converters: Dissipate heat from frequency conversion and power conversion modules.

ii. Large Solar Inverters: Cool power semiconductors and inductor components.

iii. EV Fast Charging Stations/Energy Storage Cabinets: Provide cooling for internal power modules, Battery Management Systems (BMS), etc., to prevent overheating.

5. Professional Audio and Stage Equipment:

a) Application Scenarios: High-power professional amplifiers, line array speakers, stage lighting equipment, etc. These devices generate significant heat during prolonged high-load operation.

b) Specific Equipment:

i. Professional Power Amplifiers: Dissipate heat from power tubes and transformers within the amplifier.

ii. Stage Lighting (e.g., Moving Head Lights, Follow Spots): Cool light sources and driver circuits to ensure stable light output.

6. Large Projection Equipment:

a) Application Scenarios: Cinema projectors, large conference room/auditorium engineering projectors, etc. High-brightness light sources and complex image processing units generate substantial heat.

b) Specific Equipment:

i. Laser/Xenon Lamp Projectors: Cool light source modules and optical engines to ensure brightness stability and lifespan.

Our advantage

Guangzhou Mega Technology Co., Ltd. is located in Guangzhou, Guangdong Province. We benchmark against leading cooling fan manufacturers like Delta Electronics, Nidec Corporation, Sunon, Sanyo Denki, and Orion Fans. Offering AC, DC, and EC fans, we provide customized cooling solutions for various industrial and commercial applications. Our strong R&D and technical expertise ensure our products match top manufacturers’ performance at significantly lower prices.

We pride ourselves on delivering tailored solutions to meet unique client needs. Our team collaborates closely with customers to design products that optimize cooling performance, energy efficiency, and reliability. Whether for electronic devices, industrial machinery, or commercial systems, Guangzhou Mega Technology Co., Ltd. is dedicated to providing high-quality, cost-effective solutions that exceed expectations. Our commitment to innovation and customer satisfaction keeps us at the forefront of the cooling fan industry.

Reasons to Choose Us

- Factory Direct Sales, Preferential Price: We are the manufacturer, eliminating intermediate links, and providing you with the most competitive price.

- Quality Assurance, Worry-Free After-Sales: We provide perfect after-sales service, so you can buy without worry.

- Professional Team, Customized Service: We have a professional R & D team to provide you with customized solutions.

Guangzhou Mega Technology Co Ltd