Main Menu

180x180x65mm 110V 220V RoHS Certified LED Display Durable Efficient Blower

Category AC Axial Fan

Tag AC18065 brushless fan

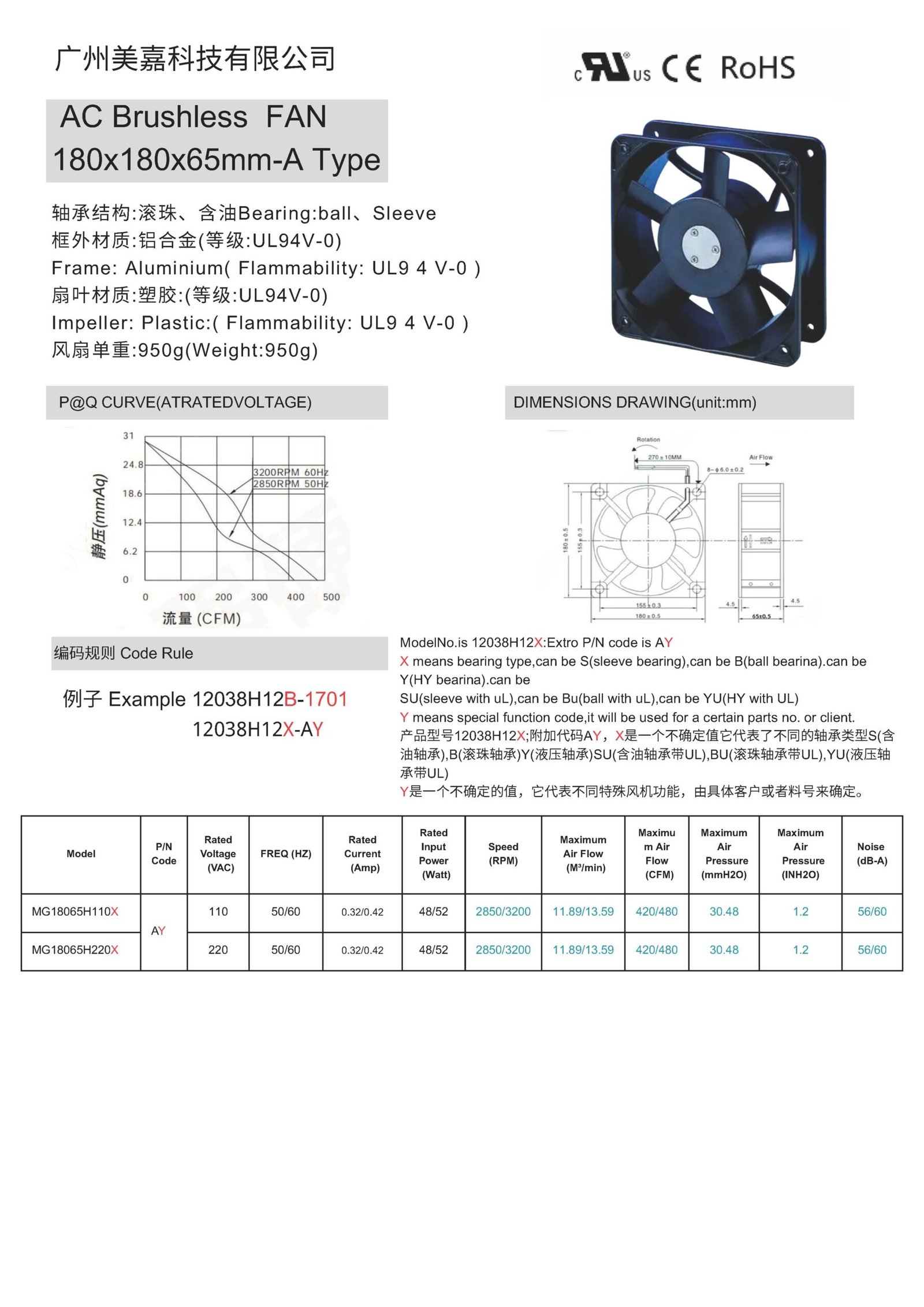

This is an AC brushless fan produced by Guangzhou Mega Technology Co., Ltd., with dimensions of 180x180x65 mm. The fan is available in 110VAC and 220VAC voltage options, with an aluminum frame and UL94V-0 grade plastic impeller, and bearings can be ball or oil type. It has strong performance, with a maximum air volume of 480 CFM, a maximum static pressure of 30.48 mm water column, and a noise level between 56-60 dB-A, suitable for industrial or commercial applications that require large air volume and high static pressure.

Parameter Value

Product Type: AC brushless fan

- Size: 180x180x65mm

- Bearing Type: ball、Sleeve

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:950g

- Rated Voltage: 110V,220V

- Rated Current: 0.32/0.42A

- Rated Input Power:48/52W

- Speed:2850/3200RPM

- Air Flow:420/480CFM

- Maximum Air Pressure:30.48mH2O

- Noise Level:56/60dB-A

Additional information

For other products not shown on website, please contact our team.

inquiry@cnmegatech.com

Product Details:

This is an AC brushless fan produced by Guangzhou Mega Technology Co., Ltd., with dimensions of 180x180x65 mm. The fan is available in 110VAC and 220VAC voltage options, with an aluminum frame and UL94V-0 grade plastic impeller, and bearings can be ball or oil type. It has strong performance, with a maximum air volume of 480 CFM, a maximum static pressure of 30.48 mm water column, and a noise level between 56-60 dB-A, suitable for industrial or commercial applications that require large air volume and high static pressure.

Parameter Value

Product Type: AC brushless fan

- Size: 180x180x65mm

- Bearing Type: ball、Sleeve

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:950g

- Rated Voltage: 110V,220V

- Rated Current: 0.32/0.42A

- Rated Input Power:48/52W

- Speed:2850/3200RPM

- Air Flow:420/480CFM

- Maximum Air Pressure:30.48mH2O

- Noise Level:56/60dB-A

| Model | Rated Voltage (VAC) | FREQ (HZ) | Rated Current (Amp) | Rated Input Power (Watt) | Speed (RPM) | Maximum Air Flow (CFM) | Maximum Air Pressure (mmH₂O) | Noise (DB-A) |

| MG18065H110X | 110 | 50/60 | 0.32/0.42 | 48/52 | 2850/3200 | 420/480 | 30.48 | 56/60 |

| MG18065H220X | 220 | 50/60 | 0.32/0.42 | 48/52 | 2850/3200 | 420/480 | 30.48 | 56/60 |

Key Features and Advantages:

Main Features:

1. Product Type & Dimensions:

1. AC Brushless Fan, measuring 180x180x65mm. This is a relatively large industrial or commercial fan.

2. AC-powered, meaning it uses alternating current directly, typically for fixed equipment rather than portable devices.

2. Materials & Safety:

1. Frame: Aluminum, with a UL94V-0 flammability rating. An aluminum frame is robust, durable, offers good heat dissipation, and the high flame retardancy adds to safety.

2. Impeller: Plastic, also with a UL94V-0 flammability rating. Lightweight and flame-retardant.

3. Bearings: Supports both Ball Bearings and Sleeve Bearings. This provides flexibility, allowing customers to choose the appropriate bearing type based on their requirements for lifespan, noise, and cost.

3. Electrical & Performance Parameters:

1. Voltage Options: Available in both 110VAC and 220VAC rated voltage versions (MG18065H110X and MG18065H220X), adapting to different regional power standards.

2. High Airflow & High Static Pressure: Maximum airflow can reach 480 CFM (or 13.59 cubic meters/minute), and maximum static pressure is 30.48 mmH2O (or 1.2 INCH2O). The P-Q curve visually demonstrates its airflow and static pressure performance at different speeds.

3. Dual-Speed Operation: From the P-Q curve and specifications table, it’s evident that it supports two different speeds (e.g., 2850 RPM and 3200 RPM), allowing for a trade-off between performance and noise.

4. Noise Level: 56-60 dB-A, which is common for industrial fans of this performance level.

5. Rated Power: 48/52 Watts.

4. Modular Naming Rule:

1. A clear model coding rule, where the letter “X” indicates the bearing type (S-Sleeve, B-Ball, BU-Ball with UL, HY-Sleeve with UL), and “Y” represents a special function code. This aids in quickly identifying product configurations.

Main Advantages:

1. Efficient Cooling Capability:

1. With its large size, high airflow, and high static pressure characteristics, this fan can provide powerful airflow to effectively dissipate heat from equipment or spaces. It is suitable for applications requiring high-efficiency cooling, such as industrial control cabinets, server racks, large power supply units, etc.

2. Wide Applicability:

1. The availability of both 110V and 220V voltage versions allows it to be sold in markets with different power standards worldwide.

2. The option for ball or sleeve bearings meets diverse customer demands regarding fan lifespan, noise, and cost. Ball bearings generally have a longer lifespan and are better suited for continuous operation, while sleeve bearings are typically more cost-effective and may be quieter (in some cases).

3. High Reliability and Safety:

1. The aluminum frame and UL94V-0 flame-retardant plastic impeller ensure the product’s structural strength, durability, and fire safety, reducing fire risks.

2. As an AC brushless fan, it is generally more stable than DC fans in certain industrial environments and avoids carbon brush wear issues, leading to lower maintenance requirements.

4. Adjustable Performance:

1. Supports dual-speed operation, allowing users to switch between maximum performance and lower noise/power consumption based on actual needs, providing operational flexibility.

5. Detailed Specification Information:

1. The product specifications are clear and detailed, including a P-Q curve, a detailed dimension drawing, and a performance parameter table. This facilitates engineering design selection and integration, reducing selection errors.

Applications

- Industrial Control and Automation Equipment:

- Industrial Control Cabinets/Distribution Cabinets: For cooling heat-generating components such as inverters, PLCs (Programmable Logic Controllers), servo drives, and power modules inside, ensuring stable operation of equipment in high-temperature environments and preventing overheating shutdowns or damage.

- Automated Production Line Equipment: Such as robot control cabinets, electrical enclosures for CNC (Computer Numerical Control) machines, automated welding equipment, etc. These devices often generate significant heat during continuous operation, requiring powerful fans for cooling.

- Power Supply and UPS Systems: Inside high-power industrial power supplies, Uninterruptible Power Supplies (UPS), and inverters, fans are needed to force-cool rectifiers, inverter modules, transformers, and other components to maintain their rated output and long lifespan.

- Circulating Cooling for Industrial Furnaces/Ovens: Used in non-high-temperature areas for cooling control components or small-scale air circulation.

- Telecommunications and Networking Equipment:

- Outdoor Communication Base Stations and Cabinets: Equipment like power amplifiers and BBUs (Baseband Units) inside base stations generate substantial heat, especially in hot outdoor environments. Powerful fans are necessary for heat dissipation to ensure communication stability and transmission rates.

- Data Center Server Racks/Network Switch Cabinets: While data centers typically have overall cooling systems, high-density servers, network switches, routers, and similar equipment often require independent fans for localized enhanced cooling within their cabinets to prevent hot spots.

- Broadcast and Television Transmitting Equipment: High-power equipment such as transmitters and amplifiers generate considerable heat during operation; fans are used to force-cool critical components.

- Medical Equipment:

- Large Medical Diagnostic Equipment: Such as CT scanners, MRI (Magnetic Resonance Imaging) equipment, X-ray machines, etc. These devices generate significant heat during operation, requiring fans to cool core components like power supply units, image processors, and high-voltage generators to ensure diagnostic accuracy and equipment reliability.

- Medical Laser Equipment: Lasers generate heat during operation; fans are used to cool laser modules and power supplies.

- Laboratory Automation Equipment: Such as blood analyzers, biochemistry analyzers, gene sequencers, etc. These precision instruments have strict requirements for internal temperature control, and fans provide the necessary heat dissipation.

- Life Support Equipment like Ventilators/Oxygen Concentrators: Although these devices have higher noise requirements, for their higher-power sections, efficient fans might still be needed for forced cooling to ensure stable long-term operation.

- HVAC (Heating, Ventilation, and Air Conditioning) and Refrigeration Equipment:

- Condensers/Evaporators of Large Commercial Air Conditioners or Precision Air Conditioners: Used as auxiliary cooling or ventilation components to enhance heat exchange efficiency.

- Industrial Chillers: Used to cool condensers in the refrigeration cycle, helping to dissipate heat.

- Air Curtain Machines/Ventilation Systems: In places requiring high-volume ventilation or the formation of an air barrier.

- Other High-Power Electronic Equipment:

- High-Power LED Displays/Lighting Equipment: Especially large outdoor or long-running displays, whose power supplies and driver modules require powerful heat dissipation.

- Electric Vehicle Charging Stations: Power modules and power components inside high-power charging stations generate significant heat, requiring fans for effective dissipation.

- Welding Machines/Laser Cutting Machines: Power modules and control circuits within these industrial processing machines require powerful fans for cooling to ensure continuous and stable operation.

Our advantage

Guangzhou Mega Technology Co., Ltd. is located in Guangzhou, Guangdong Province. We benchmark against leading cooling fan manufacturers like Delta Electronics, Nidec Corporation, Sunon, Sanyo Denki, and Orion Fans. Offering AC, DC, and EC fans, we provide customized cooling solutions for various industrial and commercial applications. Our strong R&D and technical expertise ensure our products match top manufacturers’ performance at significantly lower prices.

We pride ourselves on delivering tailored solutions to meet unique client needs. Our team collaborates closely with customers to design products that optimize cooling performance, energy efficiency, and reliability. Whether for electronic devices, industrial machinery, or commercial systems, Guangzhou Mega Technology Co., Ltd. is dedicated to providing high-quality, cost-effective solutions that exceed expectations. Our commitment to innovation and customer satisfaction keeps us at the forefront of the cooling fan industry.

Reasons to Choose Us

- Factory Direct Sales, Preferential Price: We are the manufacturer, eliminating intermediate links, and providing you with the most competitive price.

- Quality Assurance, Worry-Free After-Sales: We provide perfect after-sales service, so you can buy without worry.

- Professional Team, Customized Service: We have a professional R & D team to provide you with customized solutions.