Main Menu

18060 110V 220V Waterproof Dustproof Long Lifespan Fast Cooling Module Cooling Fan

Category AC Axial Fan

Tag AC18060 brushless fan

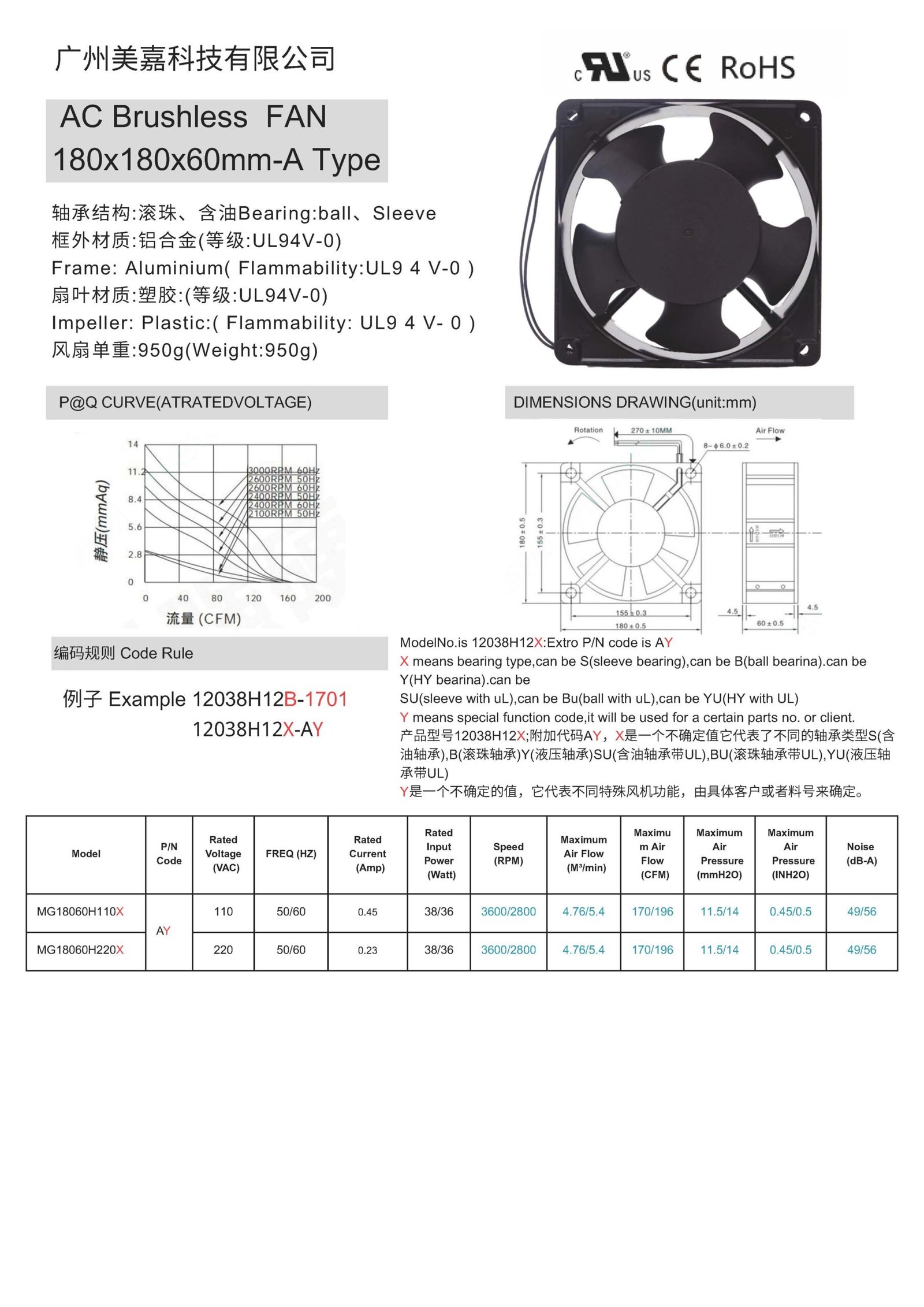

This AC brushless fan produced by Guangzhou Mega Technology Co., Ltd. is 180x180x60mm-A Type, made of aluminum alloy and flame-retardant plastic, with ball or oil-containing bearing structure, and has multiple international certifications such as CE, US and RoHS. The product provides detailed P-Q performance curves, dimension diagrams and coding rules, and lists the specific parameters of the two mainstream voltage models of 110V and 220V in tabular form, including rated current, power, speed, maximum air volume, maximum static pressure and noise level, aiming to provide efficient and reliable cooling solutions for industrial and commercial applications.

Parameter Value

Product Type: AC brushless fan

- Size: 180x180x60mm

- Bearing Type: ball、Sleeve

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:950g

- Rated Voltage: 110V,220V

- Rated Current: 0.45A(110V);0.23A(220V);

- Rated Input Power:38/36W

- Speed:3600/2800RPM

- Air Flow:170/196CFM

- Maximum Air Pressure:11.5/14mH2O

- Noise Level:49/56dB-A

Additional information

For other products not shown on website, please contact our team.

inquiry@cnmegatech.com

Product Details:

This AC brushless fan produced by Guangzhou Mega Technology Co., Ltd. is 180x180x60mm-A Type, made of aluminum alloy and flame-retardant plastic, with ball or oil-containing bearing structure, and has multiple international certifications such as CE, US and RoHS. The product provides detailed P-Q performance curves, dimension diagrams and coding rules, and lists the specific parameters of the two mainstream voltage models of 110V and 220V in tabular form, including rated current, power, speed, maximum air volume, maximum static pressure and noise level, aiming to provide efficient and reliable cooling solutions for industrial and commercial applications.

Parameter Value

Product Type: AC brushless fan

- Size: 180x180x60mm

- Bearing Type: ball、Sleeve

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:950g

- Rated Voltage: 110V,220V

- Rated Current: 0.45A(110V);0.23A(220V);

- Rated Input Power:38/36W

- Speed:3600/2800RPM

- Air Flow:170/196CFM

- Maximum Air Pressure:11.5/14mH2O

- Noise Level:49/56dB-A

| Model | Rated Voltage (VAC) | FREQ (HZ) | Rated Current (Amp) | Rated Input Power (Watt) | Speed (RPM) | Maximum Air Flow (CFM) | Maximum Air Pressure (mmH2O) | Noise (dB-A) |

| MG18060H110X | 110 | 50/60 | 0.45 | 38/36 | 3600/2800 | 170/196 | 11.5/14 | 49/56 |

| MG18060H220X | 220 | 50/60 | 0.23 | 38/36 | 3600/2800 | 170/196 | 11.5/14 | 49/56 |

Key Features and Advantages:

Main Features:

- Standardized Dimensions: The model, 180x180x60mm-A Type, represents a common industrial fan size, facilitating easy integration and replacement in various equipment.

- Multiple Bearing Options: Offers both “Ball” and “Sleeve” bearing structures, allowing users to choose based on their application’s requirements for lifespan, noise, and cost. Ball bearings generally offer a longer lifespan, while sleeve bearings are more cost-effective and have lower initial noise.

- High-Quality Materials: The outer frame is made of aluminum alloy, and the fan frame and impeller are constructed from UL94V-0 rated flame-retardant plastic. This ensures product robustness, good heat dissipation, and fire safety in case of unforeseen circumstances.

- Wide Voltage Compatibility: Provides models with both 110VAC and 220VAC rated voltages, making it suitable for different grid standards across various countries and regions, thus offering good versatility.

- Comprehensive Performance Parameters: Features a detailed P-Q curve graph (Pressure-Flow curve), along with key performance parameters such as rated current, power, speed, maximum air flow, maximum static pressure, and noise level. This enables users to select the appropriate model and evaluate its performance based on their specific needs.

- International Certifications: Carries CE, US (likely referring to UL), and RoHS certification marks, indicating compliance with relevant European and American safety and environmental standards, which enhances the product’s market competitiveness.

- Detailed Encoding Rule: Provides a clear encoding rule, allowing users to understand the meaning of the model name, particularly the bearing type and special function codes.

Main Advantages:

- High Reliability: The use of durable aluminum alloy frames and flame-retardant materials, combined with optional ball bearings, typically translates to a longer service life and higher operational stability.

- Strong Safety Features: The UL94V-0 rated flame-retardant materials significantly reduce fire hazards, meeting the high safety requirements of industrial applications.

- Wide Adaptability: The variety of voltage and bearing options, along with standardized dimensions, makes it broadly applicable in various industrial equipment, power systems, automation devices, and other scenarios requiring heat dissipation.

- Predictable Performance: Detailed performance curves and parameter tables enable users to accurately predict the fan’s behavior under different operating conditions, facilitating system design and optimization.

- International Market Access: International certifications such as CE, UL, and RoHS provide a passport for the product to enter global markets, facilitating international trade and use.

- Easy Maintenance and Replacement: Standardized dimensions and clear encoding rules make the product relatively simple to install, maintain, and replace.

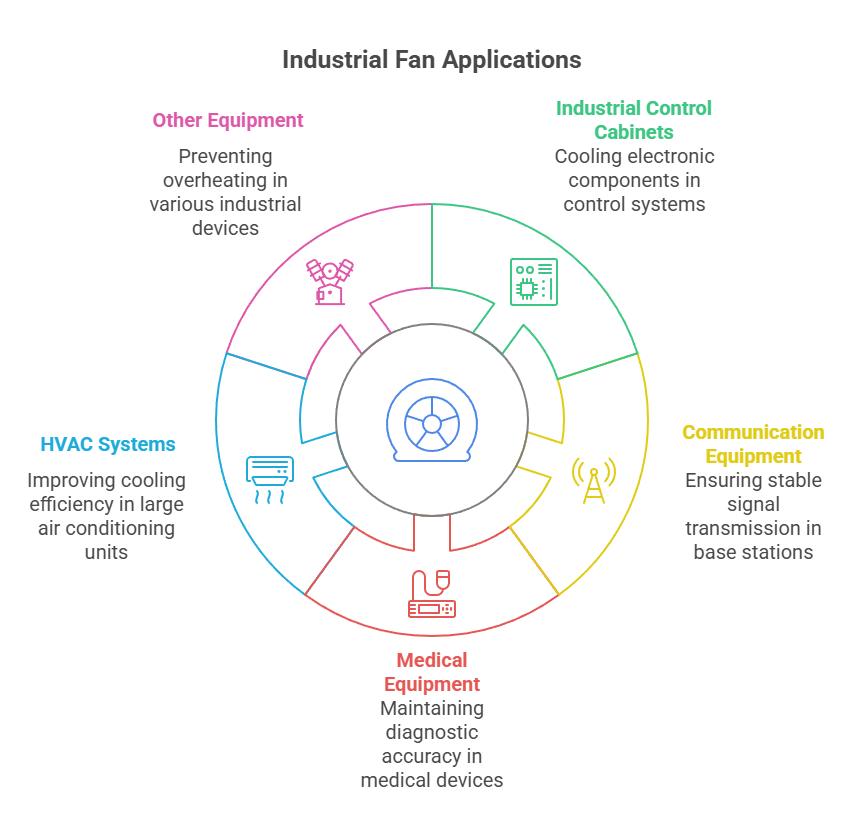

Applications

- Industrial Control Cabinets and Automation Equipment:

- PLC/DCS Control Cabinets: Within large industrial control cabinets, electronic components such as PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems) modules, inverters, and servo drives generate significant heat during operation. Fans are crucial for forced cooling to ensure stable equipment operation.

- Robot Control Systems: The electrical cabinets and drives inside industrial robots require efficient heat dissipation to guarantee the robot’s stability during long hours of high-intensity work.

- CNC Machine Tools: The electrical control boxes and spindle drive systems of CNC (Computer Numerical Control) machines generate heat. Fans are used to maintain internal temperatures, preventing overheating that could lead to reduced precision or malfunctions.

- Industrial Power Supplies and Transformers: High-power industrial power supplies, rectifiers, and inverters require powerful cooling fans to keep their operating temperatures within a safe range, extending their lifespan.

- Communication and Network Equipment:

- Communication Base Station Equipment: Devices like power amplifiers and BBUs (Baseband Units) in outdoor or indoor communication base stations require efficient heat dissipation, especially in high-temperature environments, to ensure stable and reliable signal transmission.

- Server Racks/Data Centers: Servers, switches, routers, and other network equipment within large server racks and data centers generate immense heat. Fans of this size can be used as part of the rack cooling units or for localized equipment cooling.

- Industrial Routers/Switches: Specialized network equipment designed for harsh industrial environments often requires additional fans for cooling to cope with high temperatures and dust.

- Medical Equipment:

- Large Medical Imaging Equipment: High-power modules like power supplies, control units, and high-performance computing components within large medical devices such as CT scanners, MRI machines, and X-ray machines generate substantial heat, necessitating stable and reliable fans for cooling to ensure diagnostic accuracy.

- Laboratory Analytical Instruments: High-precision analyzers, incubators, and similar equipment require precise temperature control, where fans can be used for internal air circulation and heat dissipation.

- Heating, Ventilation, and Air Conditioning (HVAC) Systems:

- Large Air Conditioning Units/Condensers: In commercial or industrial HVAC systems, this large-sized axial fan can serve as a condenser fan to exhaust heat, improving cooling efficiency.

- Ventilation and Exhaust Systems: In factory workshops, warehouses, and similar locations, it can be used for general ventilation and air exchange, expelling hot air or harmful gases.

- Other Specific Equipment:

- Large Display Screens and Billboards: The power supplies and driver modules inside outdoor LED display screens and billboards, constantly exposed to sunlight, require active fan cooling to prevent overheating.

- New Energy Equipment: Solar inverters, wind turbine control cabinets, and similar new energy devices generate heat during operation and require fans for cooling.

- Power Equipment: Inside switch cabinets, distribution cabinets, relay protection devices, and other power equipment, used for heat dissipation and air circulation.

Our advantage

Guangzhou Mega Technology Co., Ltd. is located in Guangzhou, Guangdong Province. We benchmark against leading cooling fan manufacturers like Delta Electronics, Nidec Corporation, Sunon, Sanyo Denki, and Orion Fans. Offering AC, DC, and EC fans, we provide customized cooling solutions for various industrial and commercial applications. Our strong R&D and technical expertise ensure our products match top manufacturers’ performance at significantly lower prices.

We pride ourselves on delivering tailored solutions to meet unique client needs. Our team collaborates closely with customers to design products that optimize cooling performance, energy efficiency, and reliability. Whether for electronic devices, industrial machinery, or commercial systems, Guangzhou Mega Technology Co., Ltd. is dedicated to providing high-quality, cost-effective solutions that exceed expectations. Our commitment to innovation and customer satisfaction keeps us at the forefront of the cooling fan industry.

Reasons to Choose Us

- Factory Direct Sales, Preferential Price: We are the manufacturer, eliminating intermediate links, and providing you with the most competitive price.

- Quality Assurance, Worry-Free After-Sales: We provide perfect after-sales service, so you can buy without worry.

- Professional Team, Customized Service: We have a professional R & D team to provide you with customized solutions.

Related products

-

9238 92x92x38mm 110V 220V 3000RPM Ac Cooling Fan

Read more -

2700/3200RPM AC Fan 80 X80x38mm AC Axial Flow Fan Ball Bearing Back High Speed Cooling Radiator

Read more -

80x80x38mm 8038 Ac Cooling Fan 80mm 110v 220V AC brushless Axial Fan

Read more -

60x60x30mm 110V 220V AC Axial Sleeve Bearing 6030 3500/3000PRM Speed Mini Cooling Infinity Fans

Read more -

60mm 6025 60x60x25mm 3000RPM 220V AC Cooling Fan

Read more