Introduction to Cooling in the Textile Industry

Effective cooling is a critical component in the textile industry to ensure the optimal performance and longevity of equipment. The high operational demands and dusty environments characteristic of textile manufacturing necessitate specialized cooling solutions.

Cooling Challenges in the Textile Industry

The Dangers of High-Temperature Environments

High temperatures can significantly reduce equipment efficiency, increase the risk of malfunctions, and shorten the lifespan of textile machinery. Understanding these risks is crucial for maintaining operational stability and productivity.

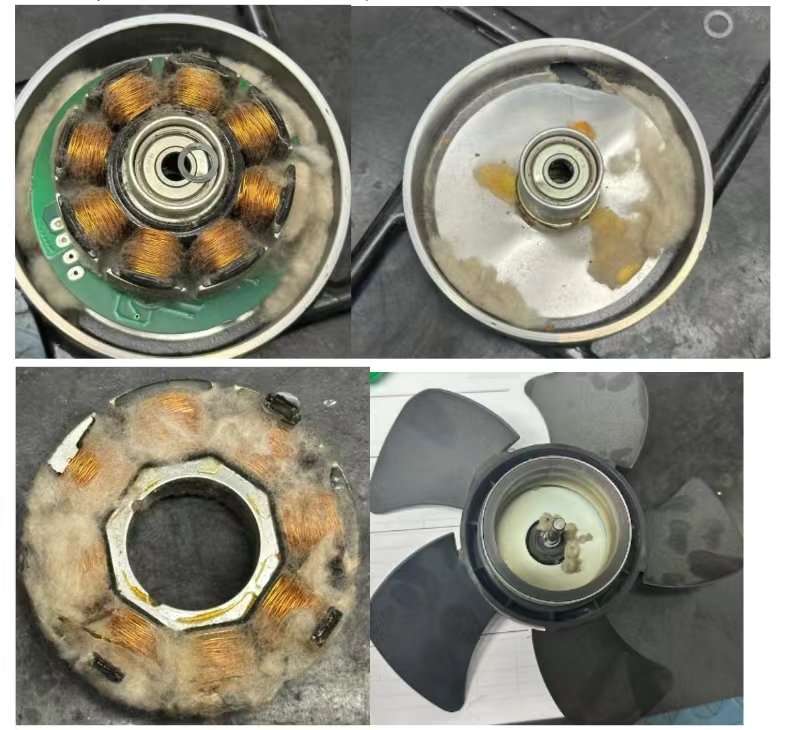

The Problem of Cotton Dust Clogging

Cotton dust accumulation is a common issue in textile mills, affecting cooling efficiency and leading to fan failures. Proper dust management is essential to ensure consistent equipment performance and longevity.Challenges in High-Dust Environments

Mega Tech Cooling Fans: The Ideal Solution

Targeted Design for Textile Industry Needs

Mega Tech cooling fans are specifically designed to meet the unique demands of the textile industry. They offer high-efficiency cooling to reduce equipment temperatures and feature dust-resistant designs to prevent cotton dust clogging.

- High-Efficiency Cooling: Our fans efficiently lower equipment temperatures, enhancing performance.

- Dust-Resistant Design: Sealed bearings and specially designed blades reduce dust accumulation, ensuring reliable operation. The fans feature a dust-proof design that covers the motor, preventing cotton fibers and other dust particles produced during manufacturing from entering the motor and causing blockage or malfunction.

- Durability and Longevity: Built with robust materials, Mega Tech fans are designed to withstand harsh conditions and extend equipment lifespan.

Advantages of Mega Tech Cooling Fans

Superior Cooling Performance

Mega Tech fans utilize advanced technology to deliver high-efficiency cooling. Available in various sizes and models, they cater to diverse cooling needs.

Reliable and Durable Quality

Made from high-quality materials, Mega Tech fans are built to last. They undergo rigorous testing to ensure consistent performance and reliability.

Comprehensive Support and Service

Mega Tech offers comprehensive support, from pre-sales consultations to post-sales services. Our expert team is ready to address any issues promptly, ensuring customer satisfaction.

Mega Tech 24V Fan Series: Tailored for the Textile Industry

12038 Fan: High Airflow, Low Noise, Long Lifespan

- High Airflow: Delivers up to 120 CFM, effectively reducing equipment temperature.

- Low Noise Level: Operates at just 35 dBA, providing a quieter working environment.

- Extended Lifespan: With a lifespan of up to 60,000 hours, maintenance costs are minimized.

17251 Fan: Powerful Cooling, Efficient Heat Dissipation

- High Airflow: Offers up to 170 CFM, ensuring efficient cooling even in high-dust environments.

- Durable Construction: Aluminum casing enhances heat dissipation.

- Wide Temperature Range: Suitable for various operating conditions.

22060 Fan: High Static Pressure, Deep Cooling

- High Static Pressure: Achieves up to 220 Pa, overcoming airflow resistance to ensure effective cooling.

- Ideal for High-Dust Environments: Specifically designed to perform well in challenging conditions, providing reliable and consistent cooling.

Here is the table containing the required details:

| Size (mm) | Voltage (VDC) | Operating Voltage (VDC) | Rated Current (A) | Speed (RPM) | Air Flow(CFM) | Power (W) | Function |

|---|---|---|---|---|---|---|---|

| 120x120x38 | 24V | 18 to 30VDC | 0.24 Amps | 2700 RPM | 114CFM | 6W | Reverse polarity protection, RD Function |

| 172x150x51 | 24V | 18 to 30VDC | 0.58 Amps | 3000 RPM | 224CFM | 18W | Reverse polarity protection, RD Function |

| 220x220x60 | 24V | 13 to 26VDC | 3.3 Amps | 3500 RPM | 630CFM | 79.2W | Reverse polarity protection, RD Function |

Benefits of Using Mega Tech Cooling Fans

Mega Tech cooling fans help textile enterprises reduce costs, enhance efficiency, and extend equipment lifespan, making them the ideal cooling solution for the textile industry. Choose Mega Tech cooling fans and empower the textile industry’s future!

Contact Mega Tech Today, Embark on Your Cooling Journey

Mega Tech boasts a team of experienced engineers and a comprehensive service system, providing customers with pre-sales consultation, model selection guidance, installation and commissioning, and after-sales service. Contact Mega Tech today to learn more.

Articles you may also like:

How to Replace a Sanyo Denki Fan with a Mega Fan

Cooling Fan Applications in Energy Storage Systems

Why Mega Fan is the best alternative to EBM Papst fan

Elevating Cooling Efficiency: Mega Refrigerator Fans

High-Performance Fans and Their Impact on the Reliability of Energy Storage PCS

Upgrade Your Refrigerator with MEGA FANS and Enjoy Superb Cooling Efficiency