Introduction: The Critical Role of Fan Selection in Thermal Management

Choosing the right cooling fan isn’t just a technical decision—it’s a make-or-break factor for your project’s success. Poor fan selection can lead to overheating, reduced product lifespan, and skyrocketing costs. For engineers, procurement managers, and product designers, understanding the differences between AC, DC, and EC fans is crucial. In this guide, we’ll compare these fan types across performance, efficiency, and applications, showing how MEGA FANS delivers cost-effective, reliable solutions to power your projects. Ready to make an informed choice? Let’s dive in.

Section 1: Breaking Down Fan Types—AC, DC, and EC

Before selecting a fan, you need to understand the core differences between AC, DC, and EC technologies. Each type has unique strengths, making them suited for specific applications. Here’s a quick breakdown.

AC Fans: Reliable for High-Power Applications

AC fans, powered by alternating current, are the traditional choice for heavy-duty cooling. They excel in high-power applications like industrial machinery and automotive systems, thanks to their robust design. However, they often lack variable speed control, which can limit efficiency in dynamic environments.

DC Fans: Precision and Energy Efficiency

DC fans, powered by direct current, offer precise speed control and energy efficiency. They’re ideal for compact electronics like servers, PCs, and consumer devices where space and power consumption are critical. For instance, MEGA’s DC fans provide high airflow with minimal energy use, making them a go-to for modern designs.

EC Fans: Combining Efficiency and Versatility

EC (electronically commutated) fans are a hybrid, blending AC’s durability with DC’s efficiency. With smart controls, they adjust speed dynamically, reducing energy waste and noise. They’re perfect for applications requiring flexibility, like medical devices or telecom systems.

Section 2: Performance Metrics—How Fans Stack Up

To choose the right fan, engineers must evaluate key performance metrics. Let’s compare AC, DC, and EC fans across airflow, energy efficiency, noise, and durability.

Airflow and Static Pressure: What You Need

Airflow (measured in CFM) and static pressure determine a fan’s ability to move air through a system. AC fans deliver high airflow for large industrial systems but struggle in compact setups. DC fans excel in smaller spaces, while EC fans balance both, offering adjustable airflow for diverse needs. For example, MEGA’s EC fans can be tailored to optimize airflow in tight enclosures.

Energy Efficiency: Saving Costs Long-Term

Energy costs add up, especially in high-uptime applications. AC fans consume more power due to fixed speeds, while DC and EC fans adjust dynamically, cutting energy use by up to 30%. MEGA’s DC and EC fans help businesses save on operating costs without sacrificing performance.

Noise and Vibration: Critical for Sensitive Applications

Noise matters in applications like medical equipment or consumer electronics. AC fans can be loud, making them less suitable for noise-sensitive environments. DC and EC fans, with variable speed controls, minimize noise and vibration. MEGA’s EC fans, for instance, are designed for near-silent operation in medical devices.

Lifespan and Reliability: Built to Last

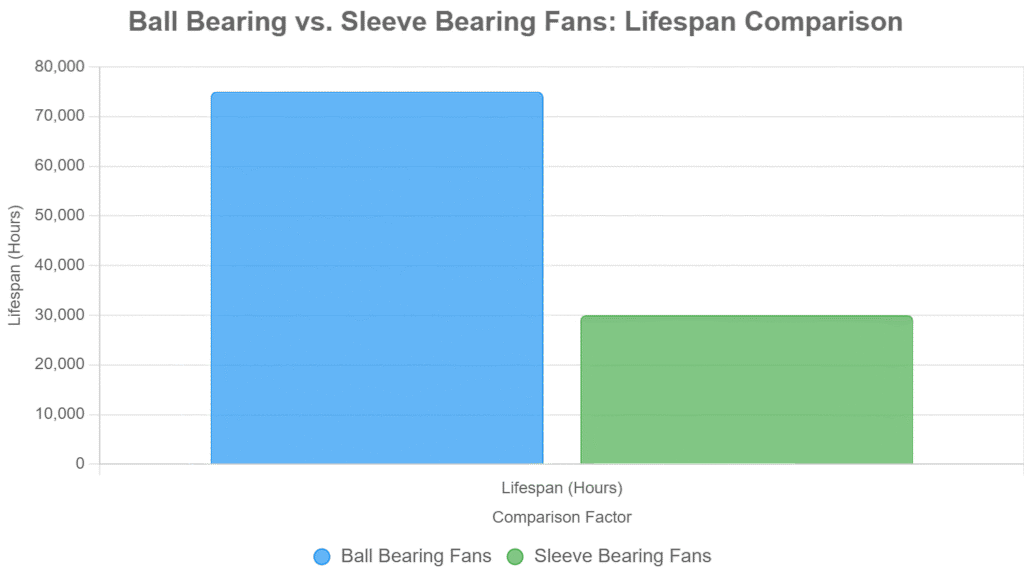

Ball Bearing vs. Sleeve Bearing: A Lifespan Comparison

The type of bearing in a fan significantly impacts its lifespan and reliability. Ball bearing fans use steel or ceramic balls to reduce friction, offering superior durability with a typical lifespan of 50,000–100,000 hours (e.g., 75,000 hours), making them ideal for continuous-use applications like servers or industrial systems. Sleeve bearing fans, using a lubricated sleeve design, have a shorter lifespan of 20,000–40,000 hours (e.g., 30,000 hours), making them suitable for less demanding applications. The chart below compares their lifespans.

Section 3: Matching Fans to Industry Applications

Different industries have unique cooling needs. Here’s how AC, DC, and EC fans align with specific applications, helping you choose the right solution.

Electronics and Computing: DC and EC Fans Excel

For servers, PCs, and consumer electronics, compact size and high efficiency are non-negotiable. DC fans provide precise cooling for tight spaces, while EC fans offer smart controls for fluctuating heat loads. MEGA’s DC fans have powered countless electronics, ensuring reliability in high-performance systems.

Automotive and Industrial: AC Fans’ Rugged Strength

In automotive and industrial systems, AC fans shine due to their ability to handle high power and harsh conditions. From factory machinery to vehicle cooling, MEGA’s AC fans deliver consistent performance, even in dusty or high-temperature environments.

Medical and Telecom: Quiet EC Fans Lead

Medical devices and telecom equipment demand low-noise, reliable cooling. EC fans, with their quiet operation and smart controls, are the top choice. MEGA’s EC fans have been used in MRI machines and 5G base stations, ensuring performance without disruption.

Startups and Prototypes: Flexible Cooling Solutions

For startups developing innovative products, cooling challenges can delay time-to-market. MEGA partners with emerging tech companies, offering customizable DC and EC fans to meet unique requirements. Our solutions have helped startups secure funding by enhancing product reliability.

Section 4: The Importance of Fan Size and Customization

Beyond fan type, size and customization are critical for optimal performance. Here’s how to get it right.

Selecting the Right Fan Size for Your System

Fan size impacts airflow and system compatibility. For compact electronics, smaller DC fans (e.g., 40mm) are ideal, while industrial systems may require larger AC fans (e.g., 120mm). MEGA’s engineering team helps you select the perfect size based on your project’s needs.

Custom Features: Materials, IP Ratings, and More

Every project is unique. MEGA offers custom solutions, from special coatings for corrosion resistance to IP-rated fans for harsh environments. Whether you need low-noise fans or high-temperature materials, we tailor solutions to fit.

Case Study: MEGA’s Custom Fan Solutions for Startups

MEGA has empowered numerous tech startups by designing custom fans, including opening molds and matching heatsinks to meet their unique cooling needs. For instance, a startup developing a compact IoT device struggled with overheating during prototyping, but MEGA’s engineering team crafted a tailored solution that optimized airflow and heat dissipation, ultimately helping them pass rigorous testing and secure significant funding. This is just one example of how MEGA drives innovation and supports startup success.

Section 5: MEGA’s Value—Cost-Effective, High-Quality Fans

Why pay more for premium brands when you can get comparable performance at a lower cost? MEGA FANS delivers value without compromise.

Why Pay More? MEGA Matches Premium Performance

Many engineers assume premium brands are the only option for reliability. However, MEGA’s fans match or exceed the performance of top brands at a fraction of the cost. Our clients have saved up to 40% by switching to MEGA without sacrificing quality.

Cost Savings with MEGA’s Solutions

From small-batch prototyping to mass production, MEGA’s competitive pricing helps businesses stay within budget. Our customizable fans reduce the need for costly redesigns, saving time and money.

Rigorous Testing for Unmatched Reliability

Every MEGA fan undergoes extensive testing for temperature, vibration, and lifespan. Our ISO-certified processes ensure your fans perform reliably, whether in a medical device or an industrial system.

Your Guide to Choosing the Right Fan

Ready to select the perfect fan? Follow this checklist and partner with MEGA for tailored solutions.

Checklist: Key Factors for Fan Selection

Ask these questions:

- What’s the required airflow (CFM)?

- Are noise levels a concern?

- What’s the operating environment (e.g., temperature, dust)?

- What’s your budget?

MEGA’s team can guide you through these decisions.

Collaborating with MEGA for Custom Solutions

Unlike one-size-fits-all suppliers, MEGA works closely with clients to design, test, and optimize cooling solutions. From concept to production, we’re your thermal management partner.

Get Started: Request a Quote Today

Don’t let cooling challenges slow you down. WTF for a free consultation or quote. Let us help you power your project with reliable, cost-effective fans.

Power Your Projects with MEGA FANS

Choosing between AC, DC, and EC fans doesn’t have to be overwhelming. By understanding their performance and applications, you can make a smart choice for your project. With MEGA FANS, you get more than just a fan—you get a partner committed to quality, innovation, and cost savings. Ready to optimize your thermal management? WTF today and let’s build something great together.

Articles you may also like:

Centrifugal Fans in Manicure Machines

DC fan in the application of stage lighting

MEGA Fans: Best Cooling Solutions for 3D Printers

Elevating Cooling Efficiency: Mega Refrigerator Fans

MEGA Tech 4010 DC Fan with Forward & Reverse Rotation

Redefining Automotive Seat Ventilation with Mega Tech’s Blower Fans