Main Menu

2600RPM 110V 220V 22580 High Temperature 225x225x80mm Axial Flow Fans

Category AC Axial Fan

Tag 22580 AC brushless fan

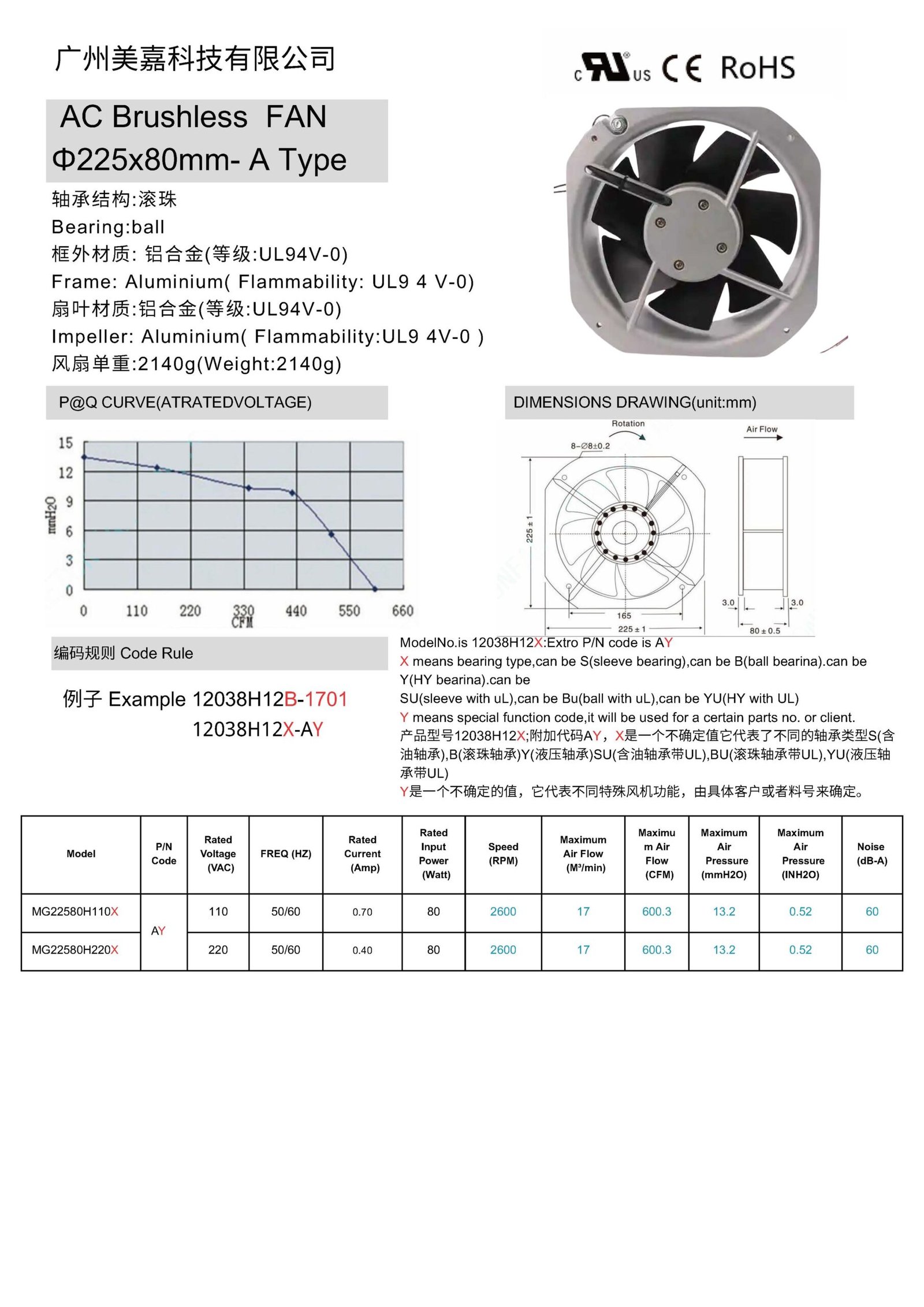

This AC brushless fan has a size of 225x80mm, with a sturdy aluminum frame, blades and impeller, and is equipped with durable ball bearings. It is available in two models: MG22580H10X and MG22580H20X, both of which support 220V voltage and 50/60Hz frequency. Among them, MG22580H10X has stronger performance, with a rated power of 80W, a maximum speed of 2600 RPM, a maximum air volume of 600.3 CFM, and a maximum static pressure of 13.2 mmH2O; while MG22580H20X is 40W, with a maximum air volume of 423.8 CFM and a maximum static pressure of 6.7 mmH2O. The noise level of both models is 60 dB-A. Its design and material characteristics indicate that this series of fans is suitable for industrial or commercial application scenarios that require high air volume and static pressure.

Parameter Value

Product Type: AC brushless fan

- Size: 225x225x80mm

- Bearing Type: ball

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Aluminum (UL94V-0)

- Weight:2140g

- Rated Voltage: 110V,220V

- Rated Current: 0.70A(110V);0.40A(220V);

- Rated Input Power:80W

- Speed:2600RPM

- Air Flow:600.3CFM

- Maximum Air Pressure:13.2mH2O

- Noise Level:60dB-A

Additional information

For other products not shown on website, please contact our team.

inquiry@cnmegatech.com

Product Details:

This AC brushless fan has a size of 225x80mm, with a sturdy aluminum frame, blades and impeller, and is equipped with durable ball bearings. It is available in two models: MG22580H10X and MG22580H20X, both of which support 220V voltage and 50/60Hz frequency. Among them, MG22580H10X has stronger performance, with a rated power of 80W, a maximum speed of 2600 RPM, a maximum air volume of 600.3 CFM, and a maximum static pressure of 13.2 mmH2O; while MG22580H20X is 40W, with a maximum air volume of 423.8 CFM and a maximum static pressure of 6.7 mmH2O. The noise level of both models is 60 dB-A. Its design and material characteristics indicate that this series of fans is suitable for industrial or commercial application scenarios that require high air volume and static pressure.

Parameter Value

Product Type: AC brushless fan

- Size: 225x225x80mm

- Bearing Type: ball

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Aluminum (UL94V-0)

- Weight:2140g

- Rated Voltage: 110V,220V

- Rated Current: 0.70A(110V);0.40A(220V);

- Rated Input Power:80W

- Speed:2600RPM

- Air Flow:600.3CFM

- Maximum Air Pressure:13.2mH2O

- Noise Level:60dB-A

| Model | Rated Voltage (VAC) | FREQ (HZ) | Rated Current (Amp) | Rated Input Power (Watt) | Speed (RPM) | Maximum Air Flow (CFM) | Maximum Air Pressure (mmH2O) | Noise (dB-A) |

| MG22580H110X | 110 | 50/60 | 0.7 | 80 | 2600 | 600.3 | 13.2 | 60 |

| MG22580H220X | 220 | 50/60 | 0.4 | 80 | 2600 | 600.3 | 13.2 | 60 |

Key Features and Advantages:

Main Features:

1. Large Size & High Airflow Design: The product model Φ225x80mm indicates a large-sized axial flow fan, specifically designed for applications requiring substantial air circulation.

2. All-Metal Construction: The frame, fan blades, and impeller are all made of aluminum or aluminum alloy, offering excellent durability, strength, and heat dissipation capabilities. All materials meet the UL94V-0 flammability rating, enhancing product safety.

3. Ball Bearing: Utilizes a ball bearing design, which generally offers a longer lifespan and better adaptability to high and low temperatures compared to sleeve bearings.

4. AC Powered: As an AC brushless fan, it operates directly on alternating current (220V, 50/60Hz), eliminating the need for additional conversion circuits, making installation and use more convenient.

5. High Performance Parameters:

a) High Airflow: The MG22580H10X model boasts a maximum airflow of 600.3 CFM (17 m3/min), while the MG22580H20X still provides 423.8 CFM (12 m3/min), meeting the cooling demands of large spaces or high-impedance systems.

b) High Static Pressure: The MG22580H10X achieves a maximum static pressure of 13.2 mmH2O, and the MG22580H20X reaches 6.7 mmH2O. This capability allows the fan to effectively overcome resistance in applications with airflow impedance, ensuring consistent airflow output.

c) Relatively High Speed: The 2600 RPM of the MG22580H10X and 1800 RPM of the MG22580H20X ensure efficient air circulation.

6. Typical P-Q Curve: A pressure-flow (P-Q) curve is provided, visually illustrating the fan’s performance at different operating points, facilitating selection of the appropriate operating condition based on user requirements.

7. Clear Dimension Drawing: Detailed dimensional markings (unit: mm) are provided, simplifying product integration and installation into equipment.

8. Detailed Coding Rule Explanation: A comprehensive explanation of the meaning of letters in the product model (e.g., bearing type, special function codes) helps users understand and select the product.

Key Advantages:

1. Exceptional Heat Dissipation Capability: The combination of large size, high airflow, and high static pressure makes it an excellent choice for thermal management applications requiring powerful air circulation and the ability to overcome resistance, such as large industrial equipment, cabinets, data centers, or HVAC systems.

2. High Reliability and Long Lifespan: The all-metal construction provides excellent mechanical strength and durability. The use of ball bearings significantly extends the fan’s operational life, reducing maintenance costs.

3. High Safety: The UL94V-0 flame retardant rating for critical components (frame, fan blades, impeller) minimizes fire hazards, enhancing product safety in demanding industrial environments.

4. Wide Applicability: 220V AC power supply and 50/60Hz frequency compatibility allow for direct use in most parts of the world without the need for power adapters.

5. Product Series Selectivity: The availability of two models with different power and performance characteristics (MG22580H10X and MG22580H20X) allows users to precisely choose based on their specific airflow, static pressure, and power consumption requirements, avoiding resource waste.

6. Robust Structure, Good Vibration Resistance: The metal casing and substantial weight (2140g) typically imply better structural stability and vibration resistance, making it suitable for harsh industrial environments.

Applications

- Industrial Equipment Cooling:

- Industrial Control Cabinets/Electrical Enclosures: These large fans are ideal for dissipating heat generated by internal components like PLCs, inverters, power supplies, and control relays, especially in manufacturing plants, automation lines, and power distribution systems. The high airflow and static pressure are crucial for moving air through dense components.

- Factory Automation Machinery: Large CNC machines, laser cutting machines, welding robots, and other automated production equipment often contain heat-generating electronics and motors that require robust cooling to maintain operational stability and precision.

- Power Generators and Transformers: For larger, industrial-scale generators and dry-type transformers, these fans can be used for forced air cooling to prevent overheating and maintain efficiency.

- Industrial Furnaces/Ovens (Cooling Sections): In the cooling zones of industrial furnaces or ovens, these fans can accelerate the cooling process of materials or components.

- Large Motors and Drives: Cooling for large industrial motors and their associated variable frequency drives (VFDs) where significant heat is produced.

- Industrial Ventilation Systems: As part of larger ventilation or exhaust systems in factories to remove hot air, fumes, or to provide general air circulation.

- Telecommunications and Data Centers:

- Server Racks/Cabinets (Side or Rear Cooling): While modern data centers often use more integrated cooling, large fans like this can still be used for supplementary cooling in older rack designs or specific high-density racks that require significant airflow to exhaust hot air.

- Communication Base Stations/Shelters: Ensuring the stable operation of networking equipment, servers, and power supplies within outdoor or remote base stations where environmental control is critical.

- Network Equipment Enclosures: Cooling for large routers, switches, and other networking hardware housed in dedicated enclosures.

- HVAC Systems (Heating, Ventilation, and Air Conditioning):

- Large Air Handling Units (AHUs): Used as primary or auxiliary fans in AHUs for commercial buildings, factories, or specialized cleanroom environments, where high volumes of air need to be moved through filters, coils, and ducts. The high static pressure is beneficial for overcoming duct resistance.

- Exhaust Systems (Commercial/Industrial Kitchens, Workshops): For ventilating large spaces where strong air extraction is needed to remove smoke, fumes, or heat.

- Ventilation for Large Public Spaces: In places like exhibition halls, warehouses, or sports arenas where general air circulation and temperature regulation are required.

- Specialized Equipment and Systems:

- Medical Imaging Equipment (e.g., MRI, CT Scanners): Certain high-power medical devices generate significant heat, and these fans could be part of their internal cooling systems or external cooling units.

- High-Power Electronic Testing Equipment: Large test benches or burn-in chambers for electronic components, where precise temperature control and substantial heat dissipation are necessary.

- Energy Storage Systems (Large Battery Banks): Cooling large arrays of batteries in industrial or grid-scale energy storage solutions to maintain optimal operating temperatures and prolong battery life.

- Custom-Built Machines/Enclosures: Any bespoke machinery or enclosures that require substantial and reliable active cooling due to heat-generating internal components.

Our advantage

Guangzhou Mega Technology Co., Ltd. is located in Guangzhou, Guangdong Province. We benchmark against leading cooling fan manufacturers like Delta Electronics, Nidec Corporation, Sunon, Sanyo Denki, and Orion Fans. Offering AC, DC, and EC fans, we provide customized cooling solutions for various industrial and commercial applications. Our strong R&D and technical expertise ensure our products match top manufacturers’ performance at significantly lower prices.

We pride ourselves on delivering tailored solutions to meet unique client needs. Our team collaborates closely with customers to design products that optimize cooling performance, energy efficiency, and reliability. Whether for electronic devices, industrial machinery, or commercial systems, Guangzhou Mega Technology Co., Ltd. is dedicated to providing high-quality, cost-effective solutions that exceed expectations. Our commitment to innovation and customer satisfaction keeps us at the forefront of the cooling fan industry.

Reasons to Choose Us

- Factory Direct Sales, Preferential Price: We are the manufacturer, eliminating intermediate links, and providing you with the most competitive price.

- Quality Assurance, Worry-Free After-Sales: We provide perfect after-sales service, so you can buy without worry.

- Professional Team, Customized Service: We have a professional R & D team to provide you with customized solutions.