Main Menu

254x89mm Premium Quality UL Certified 220V 50/60Hz Server Rack Cooling Module Cooling Fan

Category AC Axial Fan

Tag 25489 AC brushless fan

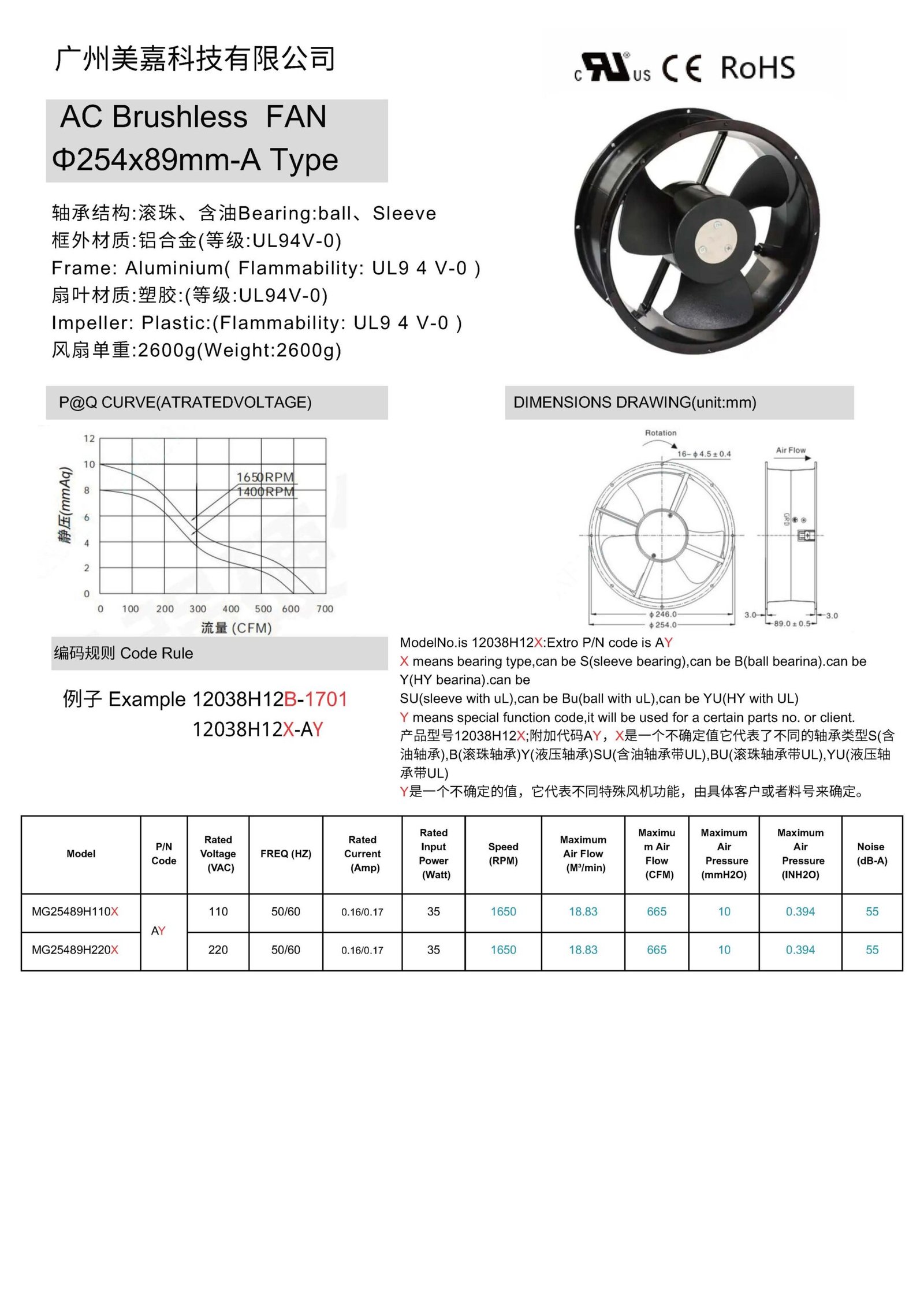

This is a 254x89mm diameter AC brushless fan produced by Guangzhou Mega Technology Co., Ltd. This fan uses an aluminum alloy frame and plastic fan blades, and is available in ball or oil-containing bearing structures. The analysis not only covers its physical dimensions, main component materials and P-Q performance curves. The product details the key technical specifications such as electrical parameters, speed, air volume, static pressure and noise level of two main models (110V and 220V), providing potential users with a comprehensive product overview.

Parameter Value

Product Type: AC brushless fan

- Size: 254x254x89mm

- Bearing Type: ball、Sleeve

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:2600g

- Rated Voltage: 110V,220V

- Rated Current: 0.16/0.17A

- Rated Input Power:35W

- Speed:1650RPM

- Air Flow:665CFM

- Maximum Air Pressure:10mH2O

- Noise Level:55dB-A

Additional information

For other products not shown on website, please contact our team.

inquiry@cnmegatech.com

Product Details:

This is a 254x89mm diameter AC brushless fan produced by Guangzhou Mega Technology Co., Ltd. This fan uses an aluminum alloy frame and plastic fan blades, and is available in ball or oil-containing bearing structures. The analysis not only covers its physical dimensions, main component materials and P-Q performance curves. The product details the key technical specifications such as electrical parameters, speed, air volume, static pressure and noise level of two main models (110V and 220V), providing potential users with a comprehensive product overview.

Parameter Value

Product Type: AC brushless fan

- Size: 254x254x89mm

- Bearing Type: ball、Sleeve

- Frame Material: Aluminum (UL94V-0)

- Blade Material: Plastic (UL94V-0)

- Weight:2600g

- Rated Voltage: 110V,220V

- Rated Current: 0.16/0.17A

- Rated Input Power:35W

- Speed:1650RPM

- Air Flow:665CFM

- Maximum Air Pressure:10mH2O

- Noise Level:55dB-A

| Model | Rated Voltage (VAC) | FREQ (HZ) | Rated Current (Amp) | Rated Input Power (Watt) | Speed (RPM) | Maximum Air Flow (CFM) | Maximum Air Pressure (mmH2O) | Noise (dB-A) |

| MG25489H110X | 110 | 50/60 | 0.16/0.17 | 35 | 1650 | 665 | 10 | 55 |

| MG25489H220X | 220 | 50/60 | 0.16/0.17 | 35 | 1650 | 665 | 10 | 55 |

Key Features and Advantages:

Key Features:

1. AC Brushless Design:

a) Feature: Utilizes AC brushless motor technology.

b) Potential Advantage: Compared to brushed motors, brushless motors typically offer a longer lifespan, lower maintenance requirements, higher efficiency, and reduced electromagnetic interference.

2. Large Size and Airflow:

a) Feature: A large fan with a diameter of Φ254mm and a thickness of 89mm.

b) Potential Advantage: Larger dimensions generally mean the ability to generate greater airflow (Maximum Air Flow up to 665 CFM) and higher static pressure (Maximum Air Pressure up to 10 mmH2O), making it suitable for applications requiring significant air circulation and the ability to overcome certain resistance.

3. Wide Voltage Compatibility:

a) Feature: Available in both 110V and 220V rated voltage versions, with key performance parameters (such as speed, airflow, static pressure, and noise) remaining consistent across both voltages.

b) Potential Advantage: This indicates good voltage adaptability in the product design, making it convenient for customers to use in various global voltage standards, reducing the complexity of managing different versions.

4. Multiple Bearing Options:

a) Feature: Supports both ball bearing and sleeve bearing structures.

b) Potential Advantage: Customers can choose the bearing type based on their specific application needs. Ball bearings typically have a longer lifespan and lower noise, suitable for continuous operation; sleeve bearings are generally more cost-effective and suitable for intermittent use or applications where noise is less critical.

5. Fire Retardant Materials:

a) Feature: The frame is made of UL94V-0 flame-retardant aluminum alloy, and the impeller is made of UL94V-0 flame-retardant plastic.

b) Potential Advantage: Enhances the product’s safety performance, effectively suppressing fire spread in case of an accident, complying with strict industrial safety standards, and suitable for equipment with high safety requirements.

6. P-Q Curve for Performance Reference:

a) Feature: Provides a static pressure-airflow performance curve graph.

b) Potential Advantage: Allows users to accurately select the optimal operating point based on the specific resistance characteristics of their system, thereby optimizing cooling or ventilation efficiency.

Main Advantages:

1. High Efficiency & Long Lifespan:

a) Combining brushless motor technology and optional ball bearings, this fan is expected to offer efficient operation and a long service life, reducing operating costs and maintenance frequency.

2. Broad Applicability:

a) Its high airflow and static pressure capabilities make it suitable for a wide range of heavy-duty industrial and commercial applications requiring powerful cooling or air circulation, such as industrial control cabinets, large power supply units, communication base stations, medical equipment, and automation machinery. The wide voltage compatibility further expands its global market applicability.

3. High Reliability & Safety:

a) The use of highly flame-retardant materials significantly enhances the product’s safety and reliability in extreme working environments, reducing fire risks.

4. Design Flexibility:

a) Multiple bearing options and clear coding rules (despite the “AY” special designation) provide customers with flexibility to customize or choose according to their specific requirements.

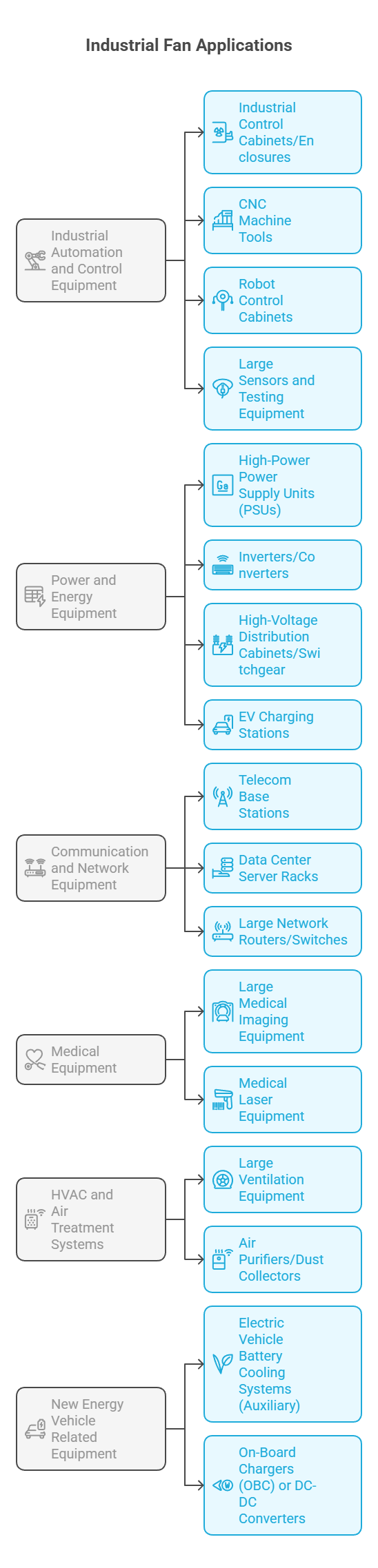

Applications

- Industrial Automation and Control Equipment:

- Industrial Control Cabinets/Enclosures: Provides forced air cooling for heat-generating components such as PLCs, variable frequency drives, servo drives, industrial computers, and power modules, ensuring stable operation of equipment in high-temperature environments.

- CNC Machine Tools: Cools critical components like machine tool control systems and spindle motor drivers to prevent overheating from affecting machining accuracy and equipment lifespan.

- Robot Control Cabinets: Dissipates heat from robot controllers and drivers, ensuring the stability and responsiveness of robot systems.

- Large Sensors and Testing Equipment: Cools internal electronic components, especially equipment operating in high-temperature or confined environments.

- Power and Energy Equipment:

- High-Power Power Supply Units (PSUs): Dissipates heat for power modules providing high-power output to telecom base stations, data centers, and industrial equipment, ensuring their efficiency and stability.

- Inverters/Converters: Particularly large-power inverters used in solar power generation, wind power generation, and UPS (Uninterruptible Power Supply) systems, which require strong heat dissipation to handle the heat generated during power conversion.

- High-Voltage Distribution Cabinets/Switchgear: Helps dissipate heat generated by internal electrical components (e.g., circuit breakers, contactors, busbars) during operation, preventing localized overheating and faults.

- EV Charging Stations: Especially high-power fast-charging stations, where internal power modules and control systems require efficient cooling to ensure charging safety and efficiency.

- Communication and Network Equipment:

- Telecom Base Stations: Cools RF units, baseband units, and power modules inside base stations, ensuring stable operation of communication networks and signal quality.

- Data Center Server Racks: While typically having dedicated data center cooling systems, large fans can serve as auxiliary or supplementary cooling for certain high-density or specially designed server racks.

- Large Network Routers/Switches: Cools high-performance network equipment to prevent data transmission interruptions or performance degradation due to overheating.

- Medical Equipment:

- Large Medical Imaging Equipment: Such as MRI (Magnetic Resonance Imaging) scanners and CT (Computed Tomography) scanners, where the precise electronic components and high-power parts inside these devices generate significant heat during operation, requiring efficient fan cooling.

- Medical Laser Equipment: Cools laser generators and control systems to ensure the stability and accuracy of laser output.

- HVAC (Heating, Ventilation, and Air Conditioning) and Air Treatment Systems:

- Large Ventilation Equipment: Serves as a core component for localized or small-scale ventilation systems, used for air circulation and exchange in workshops, warehouses, laboratories, etc.

- Air Purifiers/Dust Collectors: Especially industrial or commercial large-scale air purification equipment, which requires high-airflow fans to drive air through filtration systems.

- New Energy Vehicle Related Equipment:

- Electric Vehicle Battery Cooling Systems (Auxiliary): While battery packs typically have liquid cooling systems, this type of fan may be needed for localized cooling in certain auxiliary components or during charging processes.

- On-Board Chargers (OBC) or DC-DC Converters: Cools high-performance power electronic components.

Our advantage

Guangzhou Mega Technology Co., Ltd. is located in Guangzhou, Guangdong Province. We benchmark against leading cooling fan manufacturers like Delta Electronics, Nidec Corporation, Sunon, Sanyo Denki, and Orion Fans. Offering AC, DC, and EC fans, we provide customized cooling solutions for various industrial and commercial applications. Our strong R&D and technical expertise ensure our products match top manufacturers’ performance at significantly lower prices.

We pride ourselves on delivering tailored solutions to meet unique client needs. Our team collaborates closely with customers to design products that optimize cooling performance, energy efficiency, and reliability. Whether for electronic devices, industrial machinery, or commercial systems, Guangzhou Mega Technology Co., Ltd. is dedicated to providing high-quality, cost-effective solutions that exceed expectations. Our commitment to innovation and customer satisfaction keeps us at the forefront of the cooling fan industry.

Reasons to Choose Us

- Factory Direct Sales, Preferential Price: We are the manufacturer, eliminating intermediate links, and providing you with the most competitive price.

- Quality Assurance, Worry-Free After-Sales: We provide perfect after-sales service, so you can buy without worry.

- Professional Team, Customized Service: We have a professional R & D team to provide you with customized solutions.