Small Size. Big Problem.

Let’s be honest.

Designing for “thin” is a nightmare for thermal management.

You’re working on a smart wearable or a high-integration module. You have exactly 6mm of clearance.

Standard axial fans? They don’t have the static pressure to push air through those tight internal resistances.

If the air doesn’t move, the heat stays. And if the heat stays, your product fails.

Here is the deal: You don’t just need a “small fan.” You need a high-performance blower designed for high-resistance paths.

The 2006 Micro Blower: By the Numbers

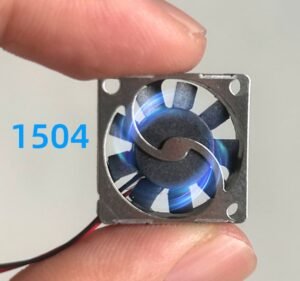

We put our 20x20x6 mm micro blower to the test.

The results? It’s a powerhouse.

- At 3.7V: It hits a stable 9,200 RPM.

- At 5.0V: It ramps up to a staggering 14,300 RPM.

[Insert Video/GIF of the 2006 Blower hitting 14,300 RPM here]

Compared to traditional axial fans, this blower provides significantly higher static pressure.

It doesn’t just “fit in” the device—it actually moves the air where it needs to go.

Why Static Pressure is the “Secret Sauce”

Most engineers focus only on CFM (airflow).

But in a 20x20x6mm space, Static Pressure is what matters.

The 2006 Blower is engineered for precise air delivery. It is the ideal solution for:

- Smart Wearables: High RPM to keep sensors cool without adding bulk.

- Imaging Equipment: Targeted cooling for high-definition image processors.

- Micro-Electronics: Stable performance in ultra-thin structures with high air resistance.

Customization: We Build What You Need

At MEGA, we’ve been a trusted partner in thermal management since 2008.

We know that “one size fits all” is a myth in engineering.

That is why the 2006 Blower supports PWM speed control and a variety of custom options.

- Custom PWM Curves: To balance noise and performance.

- Lead Wire & Connectors: Tailored to your PCB layout.

- Material Optimization: To meet specific durability requirements.

More Than a Vendor. We’re Your Partner.

Many companies just want to sell you a fan.

We want to help you build a better product.

By partnering with MEGA, you gain:

- Cost Efficiency: High-quality alternatives that help you compete better in the market.

- Time Savings: Our engineers work with your dev team to optimize thermal paths, reducing your R&D cycles.

- Scalability: Whether you need a small batch for a prototype or mass production for a global launch, we scale with you.

We’ve helped startups secure funding by solving the cooling challenges that were holding their prototypes back. We can do the same for your project.

Ready to Solve Your Thermal Challenge?

Don’t let heat be the bottleneck for your next innovation.

[Download the 2006 Blower Datasheet] or [Contact MEGA Engineering] today to discuss your custom cooling requirements.

Let’s collaborate on your next project.

Articles you may also like:

Centrifugal Fans in Manicure Machines

DC fan in the application of stage lighting

MEGA Fans: Best Cooling Solutions for 3D Printers